Manufacturing Automation Software Startup Tulip Hits Unicorn Status with $120M Raise

Why It Matters

The funding validates strong investor confidence in no‑code manufacturing software and accelerates digital transformation for factories facing labor shortages and supply‑chain volatility.

Manufacturing automation software startup Tulip hits unicorn status with $120M raise

Frontline operations software startup Tulip Interfaces Inc. said today it has raised $120 million in a late‑stage funding round that brings its valuation to more than $1.3 billion, joining the ranks of technology unicorns.

The Series D round was led by Mitsubishi Electric, which last year signed a strategic alliance agreement with the company in order to fuel its digital transformation.

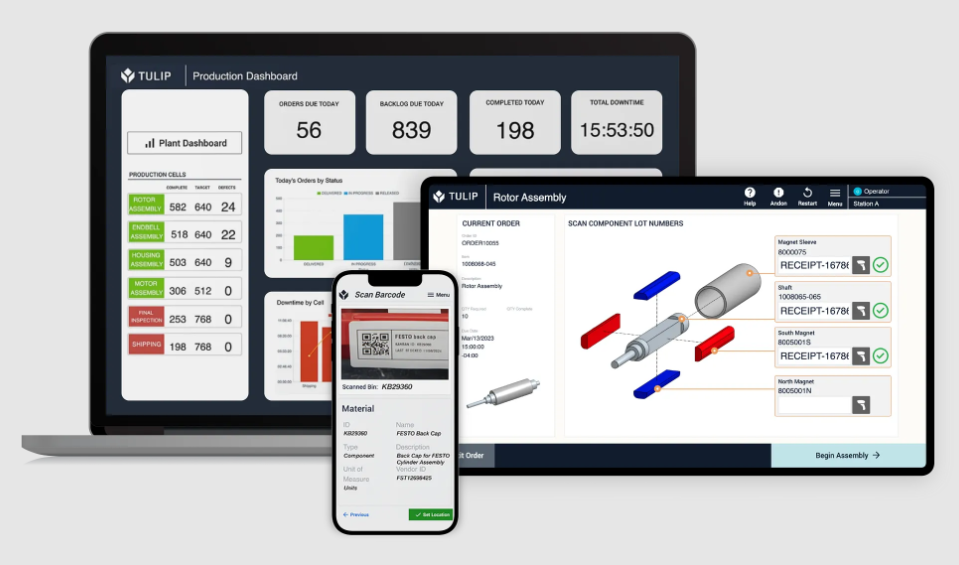

Tulip is the creator of a cloud‑hosted and no‑code frontline operations platform targeted at manufacturing firms. It allows those customers to digitally transform their production processes, connecting workers with machines, devices and systems. Through its user‑friendly interface, employees can quickly and easily build customized applications, even if they don’t possess any coding skills.

The startup positions itself as an alternative to traditional manufacturing execution systems. Its software functions as a “system of engagement” and offers various capabilities that can aid in managing manufacturing operations on the shop floor.

Its no‑code application builder uses various templates and a drag‑and‑drop interface to simplify app creation, and it has built‑in data collection and analytics tools that automatically capture information from human interactions, connected machines, sensors and smart tools such as barcode scanners or scales. This information is analyzed to provide customers with insights into performance and production bottlenecks.

Tulip’s platform integrates with existing enterprise resource planning and product lifecycle management systems via a series of connectors and application programming interfaces. It offers an “Automations” tool that lets users build visual workflows across these platforms to facilitate information exchange.

Another useful capability pertains to its integrated quality‑assurance processes, which include digital checklists, non‑conformance tracking and automated data capture. In addition, Tulip provides artificial intelligence tools such as computer vision for quality inspection and generative AI for creating documentation.

According to Tulip, its platform offers massive advantages for manufacturers. A commissioned study by Forrester Research Inc. in 2023 claimed that its customers see an average return on investment of 448 % in just three years. The same report also claims a 15 % increase in operator efficiency and a 50 % reduction in indirect labor time spent on administrative tasks.

Tulip reckons its frontline operations platform is more useful than ever at a time when manufacturing firms are dealing with challenges including supply‑chain volatility and labor shortages. It says traditional systems and paper‑based processes are too inefficient to help manufacturers overcome these problems.

It offered up a lot of data points to back up its claims, highlighting how customer adoption of its generative AI capabilities and automation tools has grown by 364 % and 519 %, respectively, over the past two years. Meanwhile, it has been growing fast, its headcount rising by 135 % in the last three years, with new offices in Budapest, Munich, Singapore, Tel Aviv and Tokyo.

Tulip Chief Executive Natan Linder said his company’s partnership with Mitsubishi Electric will enable the Japanese manufacturing giant to digitize its operations and roll out scalable AI automations and applications to improve its productivity through agile, human‑centric innovation. “Our partnership solidifies a shared commitment to human‑first digital transformation,” he said. “We are building modern, composable architectures not to automate people away, but to give them superpowers through practical use of AI.”

Image: Tulip Interfaces

Comments

Want to join the conversation?

Loading comments...