Beyond Heritage: How Hardoi’s Handloom Sustains a Living Economy

•February 10, 2026

0

Why It Matters

The sector’s growth showcases how traditional crafts can generate scalable employment and export revenue, highlighting the importance of policy support for rural manufacturing.

Key Takeaways

- •Mallawan handloom employs dozens of home-based weavers

- •ODOP program boosted market access and exhibition participation

- •Fabrics exported to US, Australia, Germany

- •Raw material costs challenge sustainability

- •Younger generation interest needed for future growth

Pulse Analysis

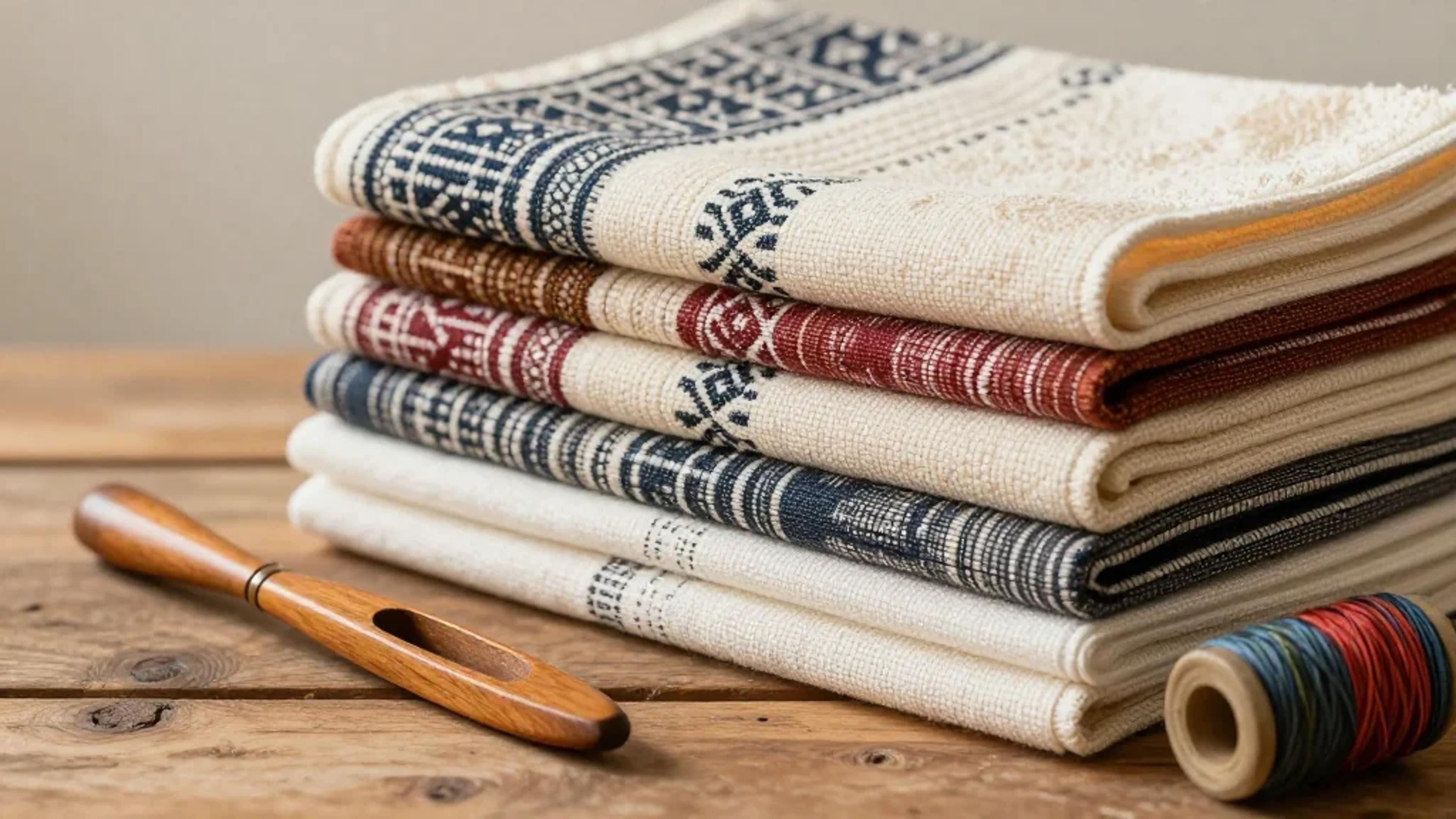

The handloom tradition of Mallawan, a cluster in Hardoi, Uttar Pradesh, has evolved from cultural heritage into a modern livelihood engine. Weavers operate from their homes, receiving yarn cones and returning finished fabrics, which preserves the tactile qualities—softness, breathability, and durability—that differentiate hand‑woven cotton from mass‑produced powerloom cloth. This decentralized production model reduces overhead, enables rapid response to design changes, and supports a broad base of artisans, many of whom lack formal employment opportunities. As a result, the sector contributes directly to household incomes while maintaining the region’s textile identity.

Government backing through the One District One Product (ODOP) programme has been pivotal in scaling Mallawan’s reach. By subsidising exhibition participation and facilitating buyer‑seller matchmaking, ODOP helped local traders connect with retailers in Delhi, Lucknow, Kanpur and beyond. The resulting order flow has propelled exports to markets such as the United States, Australia and Germany, turning a once‑regional craft into an international niche brand. Entrepreneurs like Hafizuddin Ansari exemplify this shift, reinvesting profits into looms and raw‑material procurement, thereby tightening the supply chain from yarn suppliers to end‑users.

Nevertheless, the cluster faces structural headwinds. Volatile cotton prices inflate raw‑material costs, squeezing margins for small‑scale weavers. At the same time, younger residents often gravitate toward urban jobs, threatening the transmission of weaving skills. Addressing these issues will require targeted interventions—price‑stabilisation mechanisms, skill‑training programmes, and digital platforms that showcase handloom collections to global buyers. If such measures succeed, Mallawan’s handloom ecosystem could sustain its living economy, offering a replicable model for rural manufacturing across India.

Beyond Heritage: How Hardoi’s Handloom Sustains a Living Economy

In Hardoi, Uttar Pradesh, handloom is not just a symbol of heritage—it remains part of everyday life. From towels and lungis to bedsheets, shawls, and quilt covers, handwoven textiles continue to serve households while supporting livelihoods across Mallawan and nearby weaving pockets.

This ecosystem links weavers, yarn suppliers, traders, finishers, and retailers, creating a steady local production chain. Many weavers work from their homes, receiving yarn and returning finished fabric to sellers and shopkeepers.

One such entrepreneur is Hafizuddin Ansari, a handloom trader and weaver from Mallawan. Coming from a weaving family, he grew up around looms and yarn preparation. Initially running a cloth shop that sourced fabric externally, he later shifted to local production to strengthen quality control and generate employment within the community.

In 2020, Ansari expanded into manufacturing by investing in machinery and raw material. Today, he works closely with local weavers who produce cotton-based textiles known for their distinctive handloom texture and durability.

What Sets Mallawan Apart

Production begins with yarn cones placed on a warping machine to prepare the warp threads. These are wound onto beams and mounted on handlooms, where fabric is woven with precision. Handloom fabric differs from powerloom cloth in its feel, finish, and breathability—qualities valued by both retail and wholesale buyers.

Support received under the One District One Product (ODOP) initiative has strengthened market access and participation in exhibitions. Buyers from Delhi, Lucknow, Kanpur, and Prayagraj have connected directly with Mallawan producers, leading to repeat orders and wider distribution. Today, fabrics from Hardoi reach markets across India and are exported to countries such as the United States, Australia, and Germany.

While challenges remain—such as raw material costs and sustaining interest among younger generations—the loom continues to sustain a viable, living economy in Hardoi.

0

Comments

Want to join the conversation?

Loading comments...