Fashion Industry’s Supply Chains Fight a Tariff Storm

•January 21, 2026

0

Companies Mentioned

Why It Matters

Tariff‑driven disruptions threaten profit margins and sustainability targets, making resilient, responsible supply chains a competitive imperative for fashion firms. This shift also influences broader climate‑finance and trade‑policy discussions.

Key Takeaways

- •Tariffs raise costs across apparel supply chains

- •Fashion scores 66/100 on responsible purchasing

- •Half of large firms renegotiated contracts to mitigate risk

- •Supply‑chain finance now buffers volatility beyond liquidity

- •COP30 may shape future carbon‑pricing trade rules

Pulse Analysis

The latest wave of U.S. protectionist tariffs has turned fashion supply chains into a pressure cooker, forcing brands to confront the fragility of offshore sourcing. While consumer‑goods giants such as Walmart and Target are pre‑positioning inventory to blunt cost spikes, apparel companies remain exposed, relying on a handful of factories that generate the majority of industry emissions. This concentration amplifies risk: any tariff shock can cascade into higher production costs, longer lead times, and heightened reputational exposure, especially when supplier relationships lack depth and transparency.

Responsible purchasing emerges as the strategic antidote. Companies that embed environmental and social criteria into contracts are better positioned to negotiate flexible terms, secure financing, and maintain continuity during trade turbulence. Gartner data shows nearly 50 % of large enterprises have already renegotiated contracts or shifted sourcing to mitigate tariff risk, while supply‑chain finance tools are being repurposed as volatility buffers. Yet fashion’s recent Better Buying 2025 score of 66 highlights a lag in adopting these practices, jeopardizing both cost efficiency and the sector’s climate commitments, given that six key production hubs now face tariff pressures.

Looking ahead, the upcoming COP30, despite its limited fashion representation, will likely influence carbon‑pricing mechanisms and sustainability finance that intersect with trade policy. Brazil’s $125 billion Tropical Forests Forever Facility exemplifies the scale of blended‑finance solutions that could reshape sourcing incentives. Brands that align their procurement strategies with emerging climate‑finance frameworks will not only safeguard margins but also signal ethical leadership to increasingly conscious consumers, turning tariff resilience into a long‑term competitive advantage.

Fashion industry’s supply chains fight a tariff storm

Joleen Ong, Senior Director of Brand and Retailer Membership, Cascale

Recent geopolitical developments have underscored the fragility of global supply chains, reminding businesses in constantly evolving sectors such as consumer goods and fashion that the strength of supplier relationships is one of the few persistent sources of resilience. Maintaining such relationships through responsible purchasing (based on environmental and social considerations, not just cost and quality) is not only ethical, but strategically necessary. The fashion industry is one of many that is feeling the weight of tariffs – disruptions that come at a time when it is struggling to make progress toward previously stated climate and sustainability goals. According to a 2025 benchmarking survey by the US Fashion Industry Association, 100 percent of 25 leading apparel brands and retailers identified the current administration’s protectionist stance and volatile trade relationships as a top challenge, and more than half flagged policy uncertainty, especially retaliatory tariffs, as their primary concern.

Rather than responding with short‑term cost‑cutting, major consumer‑goods companies are making strategic investments to build resilience. For example, retailers such as Walmart and Target have front‑loaded inventory to absorb tariff shocks ahead of the holiday season; and Apple chartered cargo flights to transport 1.5 million iPhones from India, an option made possible by increasing production with a key supplier. These are not just logistical moves; they are evidence of why trust‑based, responsive supply‑chain relationships matter. Responsible purchasing practices are the glue that holds supply chains together in uncertain times. Gartner reports that nearly half of large enterprises have renegotiated supplier contracts or shifted sourcing strategies to manage risks associated with the tariffs. Tools like supply‑chain finance are increasingly being used not just for liquidity, but as buffers against volatility. Such trends reflect a growing consensus: resilient, transparent, and values‑aligned supply chains are key to avoiding major disruptions and maintaining competitiveness.

Catwalk conundrum

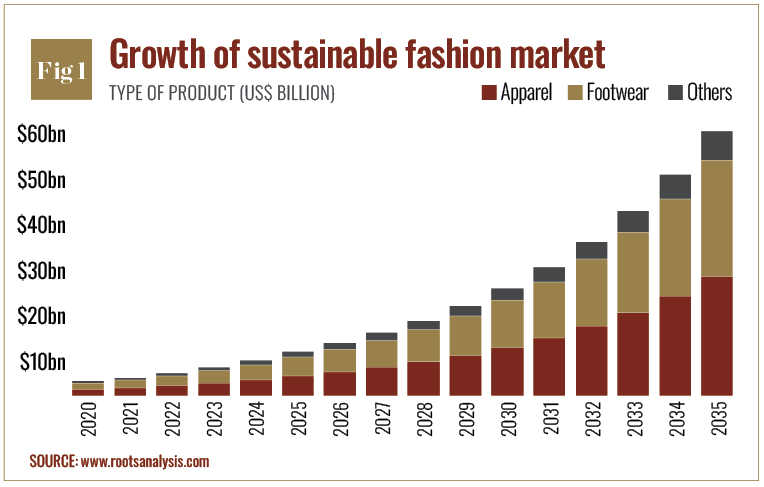

Unfortunately, the fashion sector is a laggard in this regard, scoring just 66 out of 100 in Cascale’s Better Buying 2025 Garment Industry Scorecard, with year‑on‑year declines in key areas of responsible purchasing, including cost negotiation, payment terms, and product development (see Fig 1).

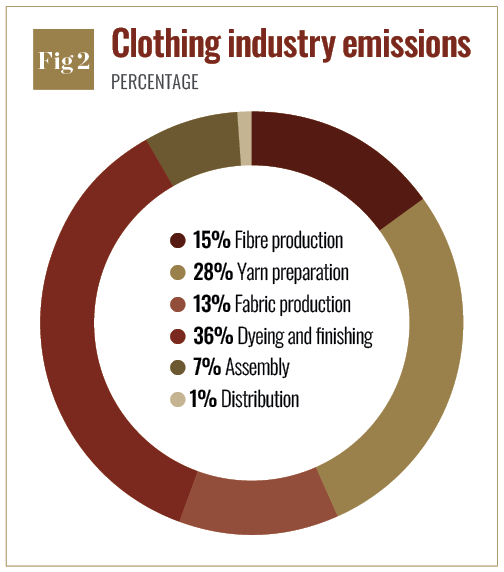

This is concerning, given that upstream effects can spread when tariffs or other external shocks hit. Production costs often need to be renegotiated, and without strong supplier relationships, shifts in production can increase delays, labour risks, and reputational exposure. The trend is also concerning for its climate implications. The fashion industry, with its complex global supply chains, is particularly vulnerable to such ripple effects. The US tariffs that went into effect on August 7 directly affect sourcing hubs with an outsized influence on the industry’s carbon footprint. Cascale finds that just 1,800 factories in nine countries account for over 80 percent of measured carbon emissions from the apparel, textile, and footwear industries (see Fig 2). Of these, six countries – China, Bangladesh, Vietnam, India, Turkey and Pakistan – have been directly affected by the new tariffs.

“Responsible purchasing practices are the glue that holds supply chains together.”

Shifting sourcing away from these hubs might avoid short‑term tariff costs, but it could also disrupt ongoing efforts to reduce emissions from these major sources. We saw this in 2018, when tariffs against China drove a production surge in Vietnam. Since it typically takes an average of 14 months for brands to add new suppliers, such rapid shifts cause a ripple effect: labour violations, longer lead times, and quality issues. Without coordinated planning, they risk undermining climate goals and working conditions alike.

Global appetite for sustainability

Though fashion is a $3 trillion industry, it is expected to have only a minimal formal presence at this year’s United Nations Climate Change Conference (COP30). As in previous years, travel budgets are being cut, and many teams are being downsized, as the industry slims down in the face of market volatility. Unlike climate‑focused gatherings such as Climate Week NYC or London Climate Action Week, COP30 will focus more on adaptation finance, carbon pricing, and nature‑based strategies than on redrawing trade or sourcing lines.

Nonetheless, industry participants should pay close attention to gauge the global appetite for sustainable finance and investment. Brazil, as COP30 president, is promoting major initiatives such as the $125 billion Tropical Forests Forever Facility, a blended‑finance tool designed to help close the $1.3 trillion annual climate‑finance gap by 2035. Moreover, discussions about carbon pricing could have a greater impact on international trade and value chains than any industry‑specific trade reform.

In short, COP30 will not offer direct relief on tariffs, but it could shape the long‑term rules of the game, linking sustainability targets, sourcing practices, and competitiveness factors through policy levers that lie beyond the fashion industry’s immediate control.

Fair purchasing practices

As trade‑related costs persist, industry leaders must shift their mindset. Resilience will not come from diplomacy or a presidential handshake, but from trust‑based relationships, fair purchasing practices, and innovations that drive sustainability. Brands and retailers should view tariffs not only as cost burdens but as stress tests for their supplier partnerships. Companies that default to price‑driven strategies risk eroding their ability to deliver quality, speed, and innovation to today’s conscientious consumer.

“As trade‑related costs persist, industry leaders must shift their mindset.”

By contrast, companies that lean into transparency and collaboration—sharing forecasts to ensure continuity, smoothing demand through level loading, and offering fairer payment terms—are more likely to avoid spikes in labour violations and preserve the market signals needed to sustain decarbonisation investments.

At a time when tariffs and climate‑related shifts can alter sourcing strategies overnight, resilient partnerships are more than operational tools. They are strategic differentiators, signalling accountability, stability, and ethical leadership to a growing list of stakeholders who are thinking about the long term.

0

Comments

Want to join the conversation?

Loading comments...