Why It Matters

The work offers a practical route to replace petroleum‑based PA12 with a biodegradable polymer, advancing sustainability targets in additive manufacturing.

Key Takeaways

- •Biocarbon boosts IR absorption, lowering laser power

- •PHB sintering window expands with filler

- •Modulus rises, elongation drops in blends

- •Powder flow and reuse still problematic

- •Fit for low‑load, short‑life SLS parts

Pulse Analysis

Selective laser sintering has been dominated by PA12 because of its forgiving processing window and reliable mechanical performance. However, growing pressure to reduce carbon footprints has spurred interest in bio‑based polymers such as polyhydroxybutyrate (PHB). PHB’s renewable origin and inherent biodegradability make it attractive for disposable fixtures, consumer goods, and medical models, yet its narrow thermal margin has limited adoption in powder‑bed fusion. The recent study addresses this gap by integrating a biocarbon filler, which acts as an efficient infrared absorber and nucleating agent, potentially reshaping the material’s sintering behavior.

Technical results indicate that biocarbon‑enhanced PHB absorbs laser energy more effectively, permitting a reduction in laser power while maintaining part density. This adjustment widens the viable sintering window, mitigating common defects such as warping, incomplete neck formation, and surface scorching. Mechanical testing shows a noticeable increase in modulus, confirming a stiffer matrix, but at the cost of reduced elongation at break. The filler also darkens the powder, influencing part aesthetics and complicating in‑situ thermal monitoring. Moreover, powder flow characteristics and long‑term recyclability remain open questions, as biocarbon may alter particle cohesion and aging behavior.

From a market perspective, PHB‑biocarbon blends could carve out a niche for environmentally conscious manufacturers seeking low‑load, short‑life components without overhauling existing SLS equipment. Service bureaus might leverage lower laser energy requirements to improve throughput and reduce operational costs. Nevertheless, broader adoption hinges on further validation of mechanical performance, dimensional stability, and powder reuse protocols. If future research confirms these parameters, the additive manufacturing industry could see a meaningful shift toward bio‑based powder options, aligning product development with circular‑economy principles.

Researchers Test SLS of PHB With Biocarbon

Selective Laser Sintering of Polyhydroxybutyrate with Biocarbon Filler

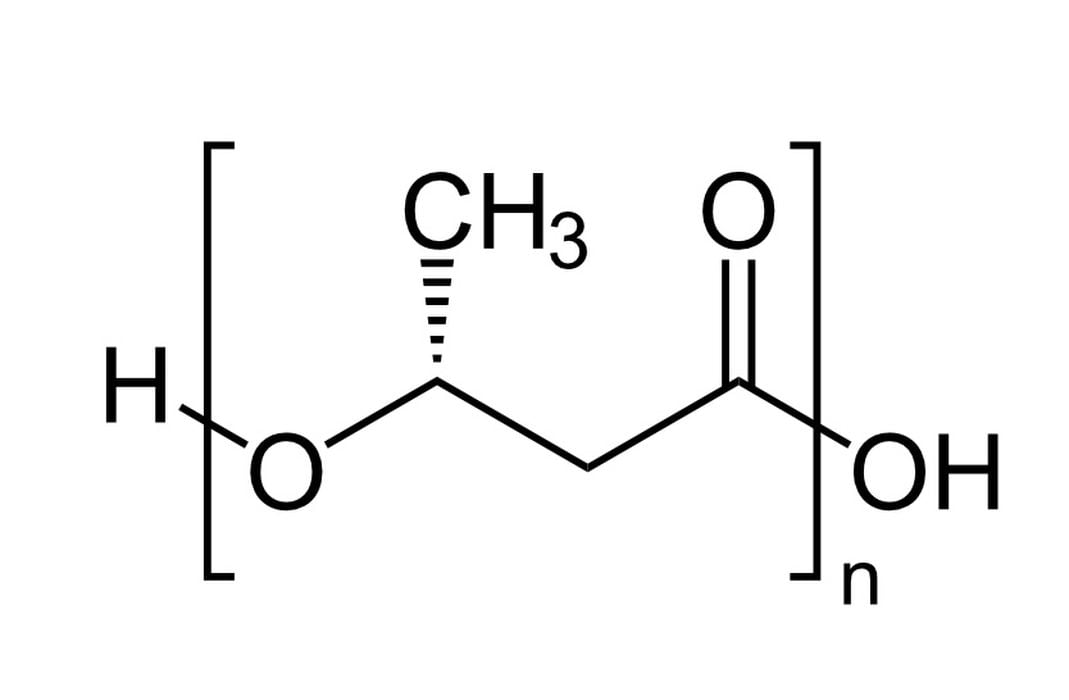

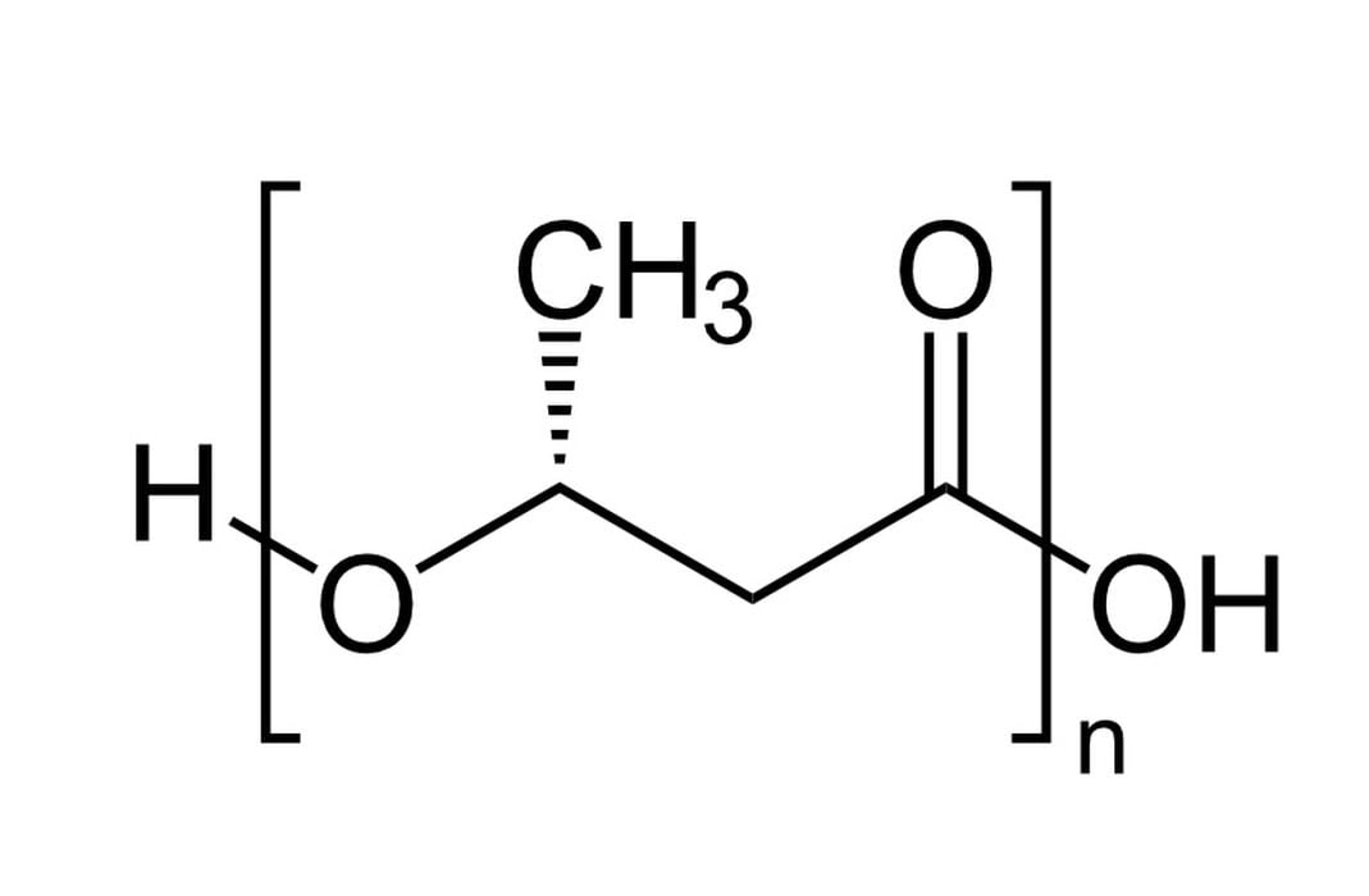

PHB chemical formula [Source: Wikipedia]

Researchers explored selective laser sintering (SLS) of polyhydroxybutyrate (PHB) with a biocarbon filler, suggesting a greener polymer option for powder‑bed additive manufacturing.

Selective Laser Sintering (SLS) has long depended on nylon powders, especially PA12, because they deliver a forgiving sintering window, solid mechanicals, and reliable throughput. Polyhydroxybutyrate (PHB), by contrast, is a biodegradable biopolyester with clear sustainability appeal but a reputation for a narrow processing window and thermal sensitivity. This study examines how processing parameters and a biocarbon reinforcement influence PHB’s behavior in SLS — a timely question as manufacturers push for lower‑carbon materials without sacrificing build reliability.

PHB’s attraction is obvious: it is produced from biogenic sources and can biodegrade under the right conditions, making it an enticing candidate for single‑use fixtures, consumer goods, or medical models that do not need the longevity of nylons. The barrier has been processability. In powder‑bed fusion, the bed temperature, laser power, scan speed, hatch spacing, and layer thickness must align with a material’s crystallization properties to produce fully fused parts without warping, caking, or soot‑like degradation. The work here tries to establish that balance for PHB and measures whether adding biocarbon can widen the process window.

Why PHB In SLS Matters

Standard polymer SLS lines run smoothly on PA12 thanks to generous temperature margins and recyclable powder behavior. PHB is different. Many biopolymers exhibit sharper transitions, making it harder to hold the bed inside a stable sintering window. Small deviations can trigger curl, poor neck growth, or incomplete fusion. If PHB can be tamed in SLS, it would extend additive options for organizations chasing sustainability targets, especially in applications where biodegradability is a feature, not a bug.

Biocarbon could help in several ways. Carbon absorbs infrared energy effectively at the wavelengths commonly used in polymer SLS, which may reduce the laser energy required to form robust necks between particles. It can act as a thermal modulator and a nucleating agent, altering crystallization behavior during cooling. As a filler, it can also stiffen the matrix, though that often trades off with ductility. The study investigates these competing effects under controlled parameter sweeps.

Processing Window and Biocarbon Effects

Although the listing does not enumerate all results, the reported focus on processing parameters suggests a classic SLS optimization: tune laser power and scan speed to reach sufficient energy density without surface burn, set hatch spacing to avoid unfused stripes, and hold the bed just below the onset of melt to curb stress. For neat PHB, that balance is typically pretty tight. With biocarbon present, a likely outcome is improved energy absorption that can lower required laser power and promote more consistent sintering at a given scan speed.

There are trade‑offs to monitor. Carbon fillers often increase modulus but can reduce elongation at break, and they almost always darken the powder, affecting part aesthetics and in‑situ thermal imaging. Filler can also influence powder flow, which in turn affects layer uniformity and, ultimately, density and dimensional accuracy. Recyclability and refresh ratios for PHB and PHB–biocarbon blends remain open questions; PA12’s dominance in SLS is partly due to predictable aging behavior after multiple thermal cycles.

Compared to PA12, PHB parts will likely post lower impact resistance and possibly lower heat deflection temperature, limiting some engineering uses. That said, for low‑load housings, jigs, educational models, and short‑life consumables, a biodegradable option could be compelling if the process proves stable across jobs and build volumes. Service bureaus and labs could also exploit faster sintering or lower laser power if the filler meaningfully improves absorptivity.

What would confirm the promise? Detailed mechanicals (tensile strength, modulus, elongation), density and porosity maps, DSC to show crystallinity shifts, warpage metrics on standardized geometries, and powder aging curves across multiple reuses. Process data from larger builds would speak to real‑world throughput and yield. Regulatory notes would matter for medical models, as would a clear end‑of‑life pathway to realize the sustainability benefit.

If these boxes get ticked, PHB blends could complement, not replace, PA12 in SLS — a niche for greener parts where performance margins allow. And if biocarbon reliably widens PHB’s sintering window, the industry may gain a practical route to bio‑based powder parts without retooling all the equipment.

0

Comments

Want to join the conversation?

Loading comments...