3D Printed Carbon Fiber Meta-Skins Improve Impact Mitigation in Foam-Core Composites

•February 19, 2026

0

Why It Matters

The findings show that 3D‑printed continuous‑fiber meta‑skins can be engineered to optimize energy absorption across different impact regimes, opening pathways for lighter, higher‑performance composite structures in aerospace, automotive and defense markets.

3D printed carbon fiber meta-skins improve impact mitigation in foam-core composites

Rodolfo Hernandez

Rodolfo Hernández is a writer and technical specialist with a background in electronics engineering and a deep interest in additive manufacturing. Rodolfo is most interested in the science behind technologies and how they are integrated into society.

Researchers at San Diego State University’s (SDSU) Experimental Mechanics Laboratoryand Advanced Manufacturing Hub have developed 3D printed continuous carbon fiber “meta-skins” designed to improve impact mitigation in composite foam-core structures. Published in Additive Manufacturing Letters, the study by Sean Eckstein, Sophia Benkirane, and George Youssef evaluates pseudo-woven composite skins fabricated using automated tow placement (ATP) and compares monocoque and sandwich configurations under low- and moderate-velocity impact. The results show that optimal performance depends on impact regime, with single-skin structures performing better at lower speeds and two-skin sandwich designs providing improved mitigation at higher velocities.

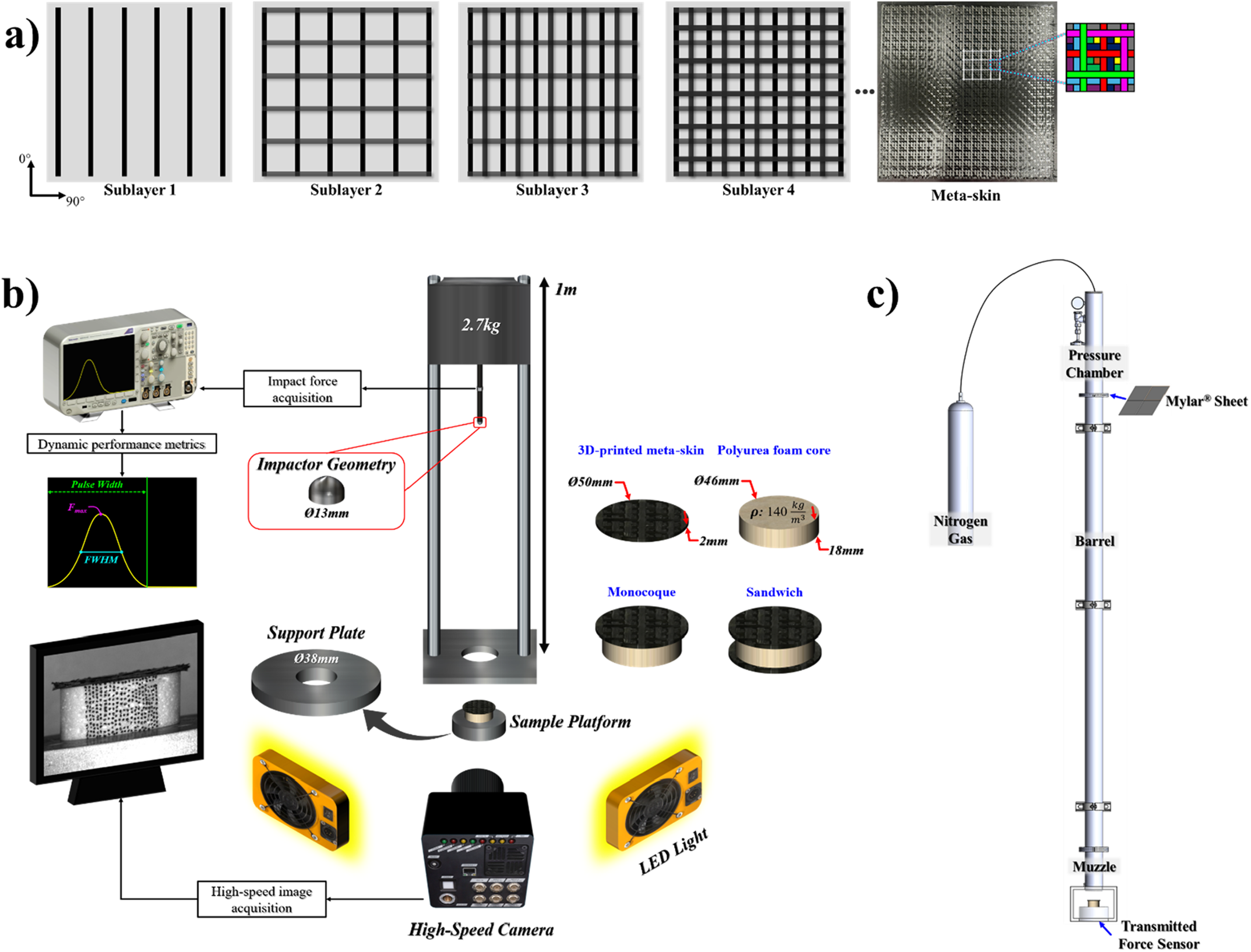

Schematic of the pseudo-woven continuous carbon fiber meta-skin fabricated using automated tow placement (ATP), along with experimental setups for low-velocity drop tower and moderate-velocity shock tube impact testing. Image via Eckstein et al., Additive Manufacturing Letters.

Pseudo-woven architecture via automated tow placement

The study reports the fabrication of continuous carbon fiber composite skins using a robotic ATP system. Rather than producing a conventional cross-ply laminate, the researchers created a pseudo-woven structure composed of alternating 0° and 90° tow sublayers. The interlaced architecture aims to improve load distribution and delamination resistance compared to traditional cross-ply laminates. Each successive sublayer was shifted laterally by 6 mm, forming an interwoven pattern through the laminate thickness.

Up to 40 sublayers were stacked to produce 2 mm-thick meta-skins. These skins were bonded to cylindrical polyurea foam pucks in two configurations. In the monocoque design, a single meta-skin capped the foam core. In the sandwich configuration, the foam was enclosed between two meta-skins. The objective was to evaluate how structural configuration and skin architecture influence dynamic impact response.

Low-velocity testing favors monocoque design

Low-velocity impact experiments were carried out with a drop tower system. A 2.7 kg hemispherical impactor hit the specimens at 4.43 m/s. High-speed imaging and digital image correlation (DIC) tracked full-field strain and deformation during impact.

Under these conditions, the monocoque configuration exhibited lower peak force and longer impact duration than the sandwich structure. The single-skin design produced a lower peak force and a longer impact duration, suggesting more spread-out energy absorption. The researchers link this to greater foam involvement, which lets the material deform within its hyper-viscoelastic plateau region. The monocoque samples absorbed nearly 100% of the impact energy and outperformed cross-ply benchmarks by approximately 15%, despite having a lower fiber volume fraction (29 vol.% versus 48 vol.%).

Force–time histories, strain distributions, and quantitative metrics including impulse and absorbed energy showed that the absence of a bottom skin enabled greater foam compression and energy dissipation at lower impact speeds.

Low-velocity (4.43 m/s) impact results comparing monocoque and sandwich configurations, including representative force–time histories and strain evolution during impact. The monocoque design exhibited lower peak force and longer impact duration under drop tower testing. Image via Eckstein et al., Additive Manufacturing Letters.

Sandwich configuration performs better at higher velocity

To assess higher strain-rate behavior, the team conducted moderate-velocity impact tests at 15 m/s using a small-scale shock tube to accelerate a projectile.

At this velocity, the performance trend reversed. The sandwich configuration reduced peak force by approximately 26% compared to the monocoque structure. Velocity–time data revealed multiple contact events during impact, suggesting altered stress-wave interactions within the confined foam core. Digital image correlation and post-impact surface reconstructions indicated that the second skin promoted more uniform compression and reduced shear at elevated impact rates. The researchers conclude that structural confinement provided by the bottom skin becomes advantageous under faster impact conditions.

Architecture-dependent dynamic performance

Across both impact regimes, the results demonstrate that mitigation performance depends strongly on structural configuration and loading rate. The monocoque design provides improved performance at lower velocities, while the sandwich structure offers enhanced protection under moderate-velocity impact.

By leveraging automated tow placement to fabricate pseudo-woven continuous fiber architectures, the study demonstrates how 3D printed composite skins can be engineered to tailor stress distribution, damage evolution, and energy absorption in foam-core systems.

Continuous fiber composites and architected materials in additive manufacturing

Continuous fiber reinforcement has become a central focus in additive manufacturing as the sector shifts from prototyping toward structural, load-bearing applications. Recent developments in continuous fiber deposition systems, including defense-backed efforts to advance process simulation and mechanical predictability, highlight the growing demand for performance-driven composite AM solutions. These initiatives underscore the importance of understanding how printed fiber architectures behave under complex and dynamic loading conditions.

At the same time, additive manufacturing has enabled the rise of architected and metamaterial-inspired structures designed to tailor mechanical response through geometry. Research into additively manufactured acoustic metamaterials has demonstrated how internal architecture can be used to manipulate wave propagation and stress distribution in ways not possible with conventional fabrication. Though focused on acoustics, such work illustrates the growing emphasis on architected materials, where structural geometry dictates performance, an approach mirrored in the SDSU study.

Composite material innovation has also expanded in parallel, with high-performance reinforced polymer systems being positioned for aerospace and industrial environments. However, much of that advancement has centered on material chemistry and reinforcement content. The present study shifts attention toward fiber topology and structural configuration, showing how additively manufactured continuous fiber architectures can influence impact mitigation across different velocity regimes. In doing so, it reinforces the growing role of architected composite design in next-generation structural applications.

The3D Printing Industry Awardsare back. Make your nominations now.

Do you operate a 3D printing start-up? Reach readers, potential investors, and customers with the3D Printing Industry Start-up of Yearcompetition.

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the3D Printing Industry newsletteror follow us onLinkedIn.

While you’re here, why not subscribe to ourYoutubechannel? Featuring discussion, debriefs, video shorts, and webinar replays.

Featured image shows schematic of the pseudo-woven continuous carbon fiber meta-skin fabricated using automated tow placement (ATP), along with experimental setups for low-velocity drop tower and moderate-velocity shock tube impact testing. Image via Eckstein et al., Additive Manufacturing Letters.

0

Comments

Want to join the conversation?

Loading comments...