Heimatec Speed Increasers for Lathes and Swiss-Style Machines

•February 19, 2026

0

Why It Matters

Higher spindle speeds enable smaller tools to cut faster, boosting productivity and reducing per‑part cost in high‑volume, precision markets like medical device manufacturing.

Key Takeaways

- •Gear ratios up to 1:4 deliver 48,000 rpm

- •Configurations include straight, offset, 90°, universal adjustable

- •Supports BMT, Swiss, VDI turret interfaces

- •In stock for Citizen, Tsugami, Star, Haas machines

- •Boosts productivity and tool life in high‑precision shops

Pulse Analysis

The surge in demand for miniature components—driven by medical implants, aerospace parts, and consumer electronics—has forced machine shops to seek higher spindle speeds without sacrificing rigidity. Speed increasers like Heimatec’s address this need by multiplying motor output through precision gearing, allowing existing lathes to achieve up to 48,000 rpm. This capability shortens cycle times for micro‑features, reduces tool wear, and expands the feasible material palette, especially for hard‑to‑cut alloys used in critical applications.

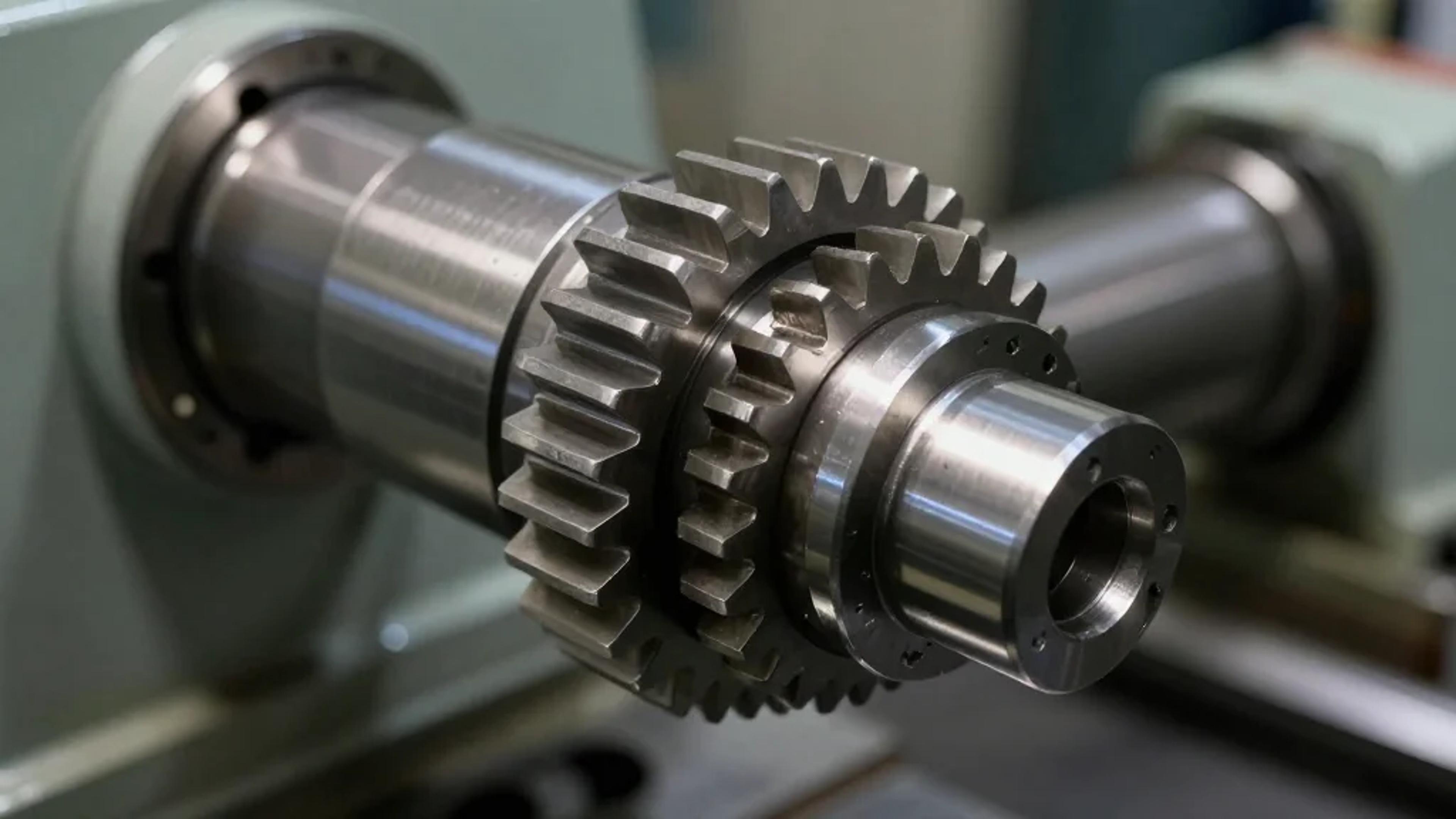

Heimatec’s portfolio distinguishes itself through modular design options. Straight, offset, 90°, and universal‑adjustable configurations let users tailor the speeder to the geometry of the turret and the coolant delivery method—external spray or internal flow. Compatibility spans BMT, Swiss‑style, and VDI interfaces, ensuring seamless integration with popular turret systems from Citizen, Tsugami, Star, Nakamura, Miyano, DN Solutions and Haas. The gear ratios of 1:2, 1:3 and 1:4 provide a scalable speed boost, while high‑quality bearings and hardened components promise long service life under continuous high‑rpm operation.

For manufacturers, the business impact is immediate. Faster spindle speeds translate to higher part throughput and lower labor costs, while the precision of Heimatec’s gearing reduces cycle‑time variability. Platinum Tooling’s ready‑to‑ship inventory further minimizes downtime, enabling OEMs and contract shops to meet tight delivery windows. As the machine‑tool industry continues to pivot toward ultra‑precision, high‑volume production, accessories that extend the performance envelope of existing equipment—like Heimatec speed increasers—will become essential competitive differentiators.

Heimatec Speed Increasers for Lathes and Swiss-Style Machines

Platinum Tooling Technologies Announces Heimatec Speed Increasers

Prospect Heights, IL — Platinum Tooling Technologies, exclusive importer of Heimatec live tools and angle heads, offers a variety of products designed to enhance the rpm capabilities of machines, from the largest turning centers to the smallest Swiss‑type CNC lathe.

Heimatec speed increasers are available in a complete range designed for popular live‑tool lathes and Swiss‑style machines, offering gear ratios of 1:2, 1:3, and 1:4 with maximum speeds of 48,000 rpm. Design configurations include straight, offset, 90°, and universal adjustable, while tools can be produced with external or internal coolant. Mounting options include BMT, Swiss‑style machine, and VDI interfaces to suit a wide range of machine‑tool setups.

With the growth of medical and other high‑precision, high‑volume manufacturing, and the use of Swiss‑style machines, speed increasers have become vital to the machine‑tool industry. As components get smaller, the cutting tools required also get smaller, which necessitates higher rpm to provide maximum performance. Heimatec speeders for Citizen, Tsugami, and Star machines are in stock at Platinum Tooling.

Speed increasers for BMT turrets, including Nakamura, Miyano, DN Solutions, and Haas, are also in stock. Additional models are available from factory inventory with short lead times. Engineered for efficiency and precision with the highest‑quality components, these tools deliver increased productivity, long service life, and cost savings for the busy machine shop or OEM production department.

To learn more about the speeder accessories available through Platinum Tooling, as well as other precision machine‑tool accessories, contact Preben Hansen, president of Platinum Tooling, at (847) 749‑0633.

Star speeder

Axial live tool speeder

Radial live tool speeder

0

Comments

Want to join the conversation?

Loading comments...