Hexagon Launches New Certified Marker-Free HYPERSCAN 3D Scanner

•February 20, 2026

0

Companies Mentioned

Why It Matters

The technology speeds high‑precision shop‑floor inspection, cutting labor costs and boosting throughput for manufacturers of oversized components. Its marker‑free approach also simplifies traceability compliance, giving users a competitive quality advantage.

Key Takeaways

- •Marker‑free scanning cuts setup time by up to 30 minutes

- •HYPERSCAN reaches 7 m range, 8.3 M points per second

- •Certified VDI/VDE 2634‑3, validated by ISO 17025 lab

- •Integrates with PC‑DMIS, Inspire, SpatialAnalyzer, robots

- •Red Bull Powertrains uses scanner for F1 component verification

Pulse Analysis

The rise of marker‑free metrology reflects a broader industry push to eliminate the bottlenecks associated with traditional target‑based scanning. Conventional setups require manual placement of reference markers, adding 15 to 30 minutes per part and often demanding a controlled environment. Hexagon’s HYPERSCAN tackles these constraints by using optical tracking to maintain positional stability, allowing engineers to capture accurate data directly on the factory floor. This shift not only reduces downtime but also expands the feasible inspection envelope for components that are too large or heavy to move to fixed CMMs.

From a technical perspective, HYPERSCAN’s Ultra and Super configurations deliver up to 8.3 million points per second across a 7‑meter capture range, rivaling stationary systems while retaining handheld flexibility. The scanner’s certification to VDI/VDE 2634‑3 and ISO 17025 validation assures traceability, a critical factor for regulated sectors such as aerospace and energy. Seamless integration with platforms like PC‑DMIS, Inspire, and SpatialAnalyzer, plus support for robotic arms and rotary tables, enables automated inspection cells that feed real‑time data into quality‑control pipelines. Real‑world validation at Red Bull Powertrains demonstrates the scanner’s ability to handle reflective carbon‑fiber parts and deliver millimetric tolerance feedback within race‑car development cycles.

Looking ahead, the adoption of portable, marker‑free scanners is likely to accelerate across automotive, aerospace, and precision manufacturing as manufacturers seek faster, more flexible quality assurance. The combination of high point density, wireless operation, and AI‑driven edge detection positions HYPERSCAN as a catalyst for fully digitized production lines, where inspection can occur continuously without interrupting workflow. As the metrology market embraces Industry 4.0 standards, solutions that blend accuracy, speed, and ease of integration will become essential differentiators for firms aiming to maintain competitive lead times and stringent compliance requirements.

Hexagon Launches New Certified Marker-Free HYPERSCAN 3D Scanner

Ada Shaikhnag

With a background in journalism, Ada has a keen interest in frontier technology and its application in the wider world. Ada reports on aspects of 3D printing ranging from aerospace and automotive to medical and dental.

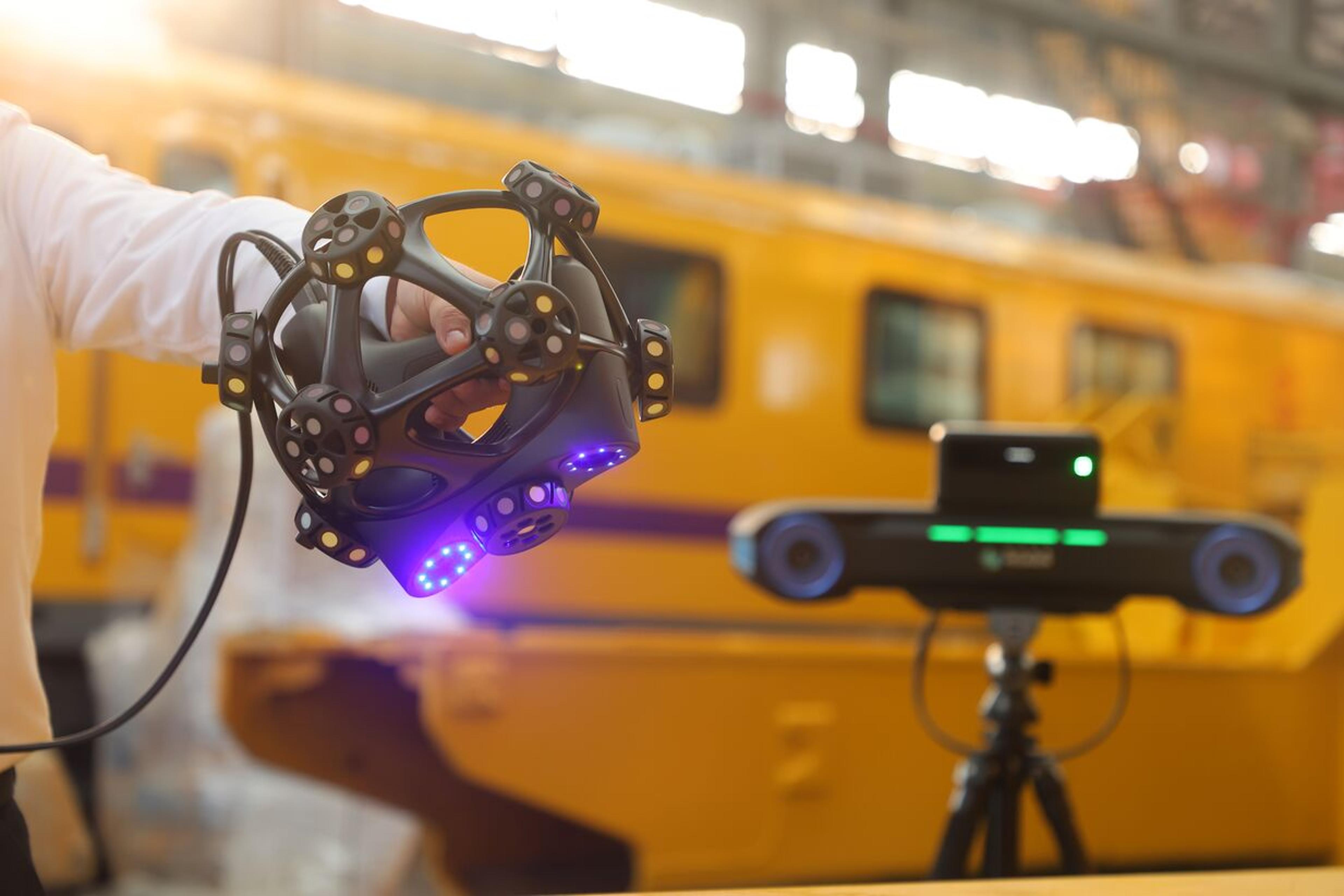

Swedish software developer Hexagon has introduced a portable 3D scanning system that removes the need for reference targets, addressing setup delays in production inspection workflows.

Certified to VDI/VDE 2634‑3 and validated by an ISO 17025 accredited laboratory, the HYPERSCAN 3D scanner is available in two configurations for components up to 7 metres.

Reference targets typically add 15 to 30 minutes to each measurement setup, and longer for complex assemblies or when recalibration is required after equipment movement. That overhead becomes significant when inspecting large fabrications such as turbine housings, aerospace structures, or heavy press tooling that cannot be moved to fixed coordinate measuring machines (CMMs).

In these cases, measurements must be performed on the factory floor under less controlled conditions while still meeting documented accuracy standards. To support this, HYPERSCAN uses optical tracking to maintain measurement stability without targets. Manufacturers will nevertheless need to demonstrate traceability within their own quality systems and confirm compliance with internal and external audit requirements.

Built for Production Environments

The system operates in handheld or robotic configurations and connects to existing metrology software platforms including PC‑DMIS, Inspire, and SpatialAnalyzer, as well as other third‑party applications. Data transfer occurs through a single‑click interface. Integration with rotary tables, industrial robots, collaborative robots, and PRESTO automated inspection cells is supported through a dedicated kit.

The scanner generates high‑resolution measurement data and includes a hole detection function that identifies holes during scanning. Edge recognition software adjusts to surface variation across materials. The scan area measures 610 × 640 mm, with multiple scanning modes enabling capture of detailed features and larger surfaces within a single workflow.

For production deployment, the unit incorporates a Wi‑Fi 6 or 7 module and an integrated battery, allowing use on factory floors, at on‑site locations, or in confined areas.

According to the Swedish developer, two versions are now available globally. The HYPERSCAN Ultra model provides a range of up to 5.5 m. The HYPERSCAN Super extends the range to 7 m and reaches capture speeds of up to 8.3 million points per second.

Hexagon has positioned the 3D scanner for automotive, aerospace, energy and precision manufacturing applications, where large installed components often require in‑situ inspection.

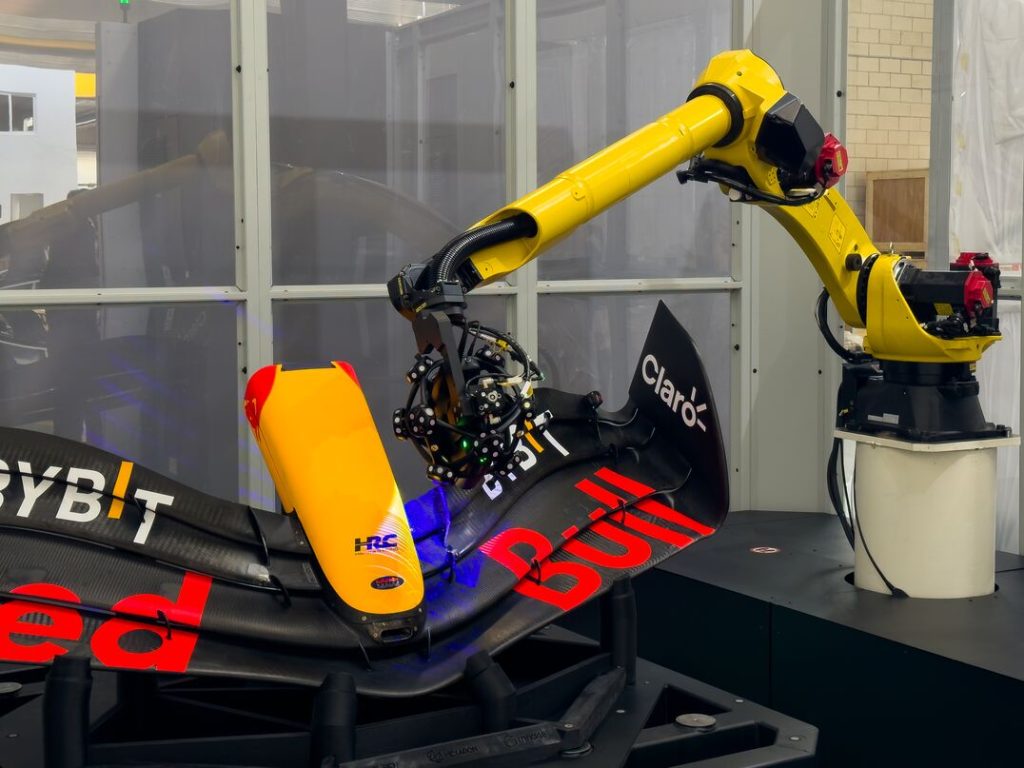

The company’s portable metrology systems were deployed in Formula One (F1) manufacturing environments where dimensional verification operated under strict time and accuracy constraints. At Oracle Red Bull Racing’s Milton Keynes facility, engineers validated components within millimetric tolerances before race deployment.

Mark Foden, Head of Quality Control at Red Bull Powertrains, noted that scanning reflective surfaces such as carbon‑fiber components with resin layers had previously limited non‑contact measurement methods. The team scanned components throughout manufacturing to provide real‑time feedback to design teams, identifying deviations across development cycles where thousands of design changes occurred each season.

Rethinking Alignment in Handheld 3D Scanning

As handheld systems move deeper into production inspection, manufacturers are redesigning alignment strategies to reduce target placement while preserving dimensional control.

In 2023, Shining 3D launched the FreeScan Trio 3D scanner with marker‑free operation through a 98‑laser‑line mode. That system captures 3.01 million points per second across a 650 × 580 mm scan area. It achieves 0.02 mm accuracy with markers and a volumetric accuracy of 0.02 mm + 0.015 mm/m in marker‑free mode. The device also offers three additional scanning modes that work with traditional markers.

Hexagon’s own MARVELSCAN, part of the company’s first handheld scanner line, employs a built‑in photogrammetry system to enable target‑free 3D scanning. The company describes this as particularly advantageous for large and repetitive components. MARVELSCAN allows both the scanner and parts to move freely during measurement and includes wireless operation without cables or referencing hardware.

0

Comments

Want to join the conversation?

Loading comments...