North Aircraft Industries Is Manufacturing the Cavorite X7 VTOL Composite Wings

•February 18, 2026

0

Why It Matters

The collaborations accelerate composite‑intensive VTOL development, reducing weight and cost while bolstering market confidence through substantial financing and clear certification pathways.

Key Takeaways

- •NAI to produce Cavorite X7 composite wings

- •Wing design features opening covers with twelve lift fans

- •Eve completed first full‑scale eVTOL flight in Brazil

- •Eve secured $150 million debt, total funding $1.2 billion

- •Certification targeted for 2027 with FAA/EASA engagement

Pulse Analysis

The partnership between North Aircraft Industries and New Horizon Aircraft underscores a growing trend: aerospace firms are turning to specialist composite manufacturers to meet the demanding weight‑and‑strength ratios required by next‑generation VTOL platforms. By integrating in‑house structural testing, NAI can iterate designs faster, cut tooling cycles, and guarantee that the Cavorite X7’s wing covers—housing twelve electric lift fans—maintain integrity both in vertical lift mode and during high‑speed cruise. This approach not only shortens time‑to‑market but also sets a benchmark for modular wing architectures that could be replicated across the emerging urban air mobility (UAM) ecosystem.

Eve Air Mobility’s recent milestones illustrate how technical validation and capital acquisition are converging to propel eVTOL commercialization. The successful uncrewed flight at Embraer’s facility confirmed the aircraft’s fly‑by‑wire system, fixed‑pitch rotors, and overall aerodynamic concept, providing high‑fidelity data essential for safety cases and certification dossiers. Coupled with a $150 million debt facility—bringing total funding to about $1.2 billion—the company now possesses the liquidity to scale prototype production, deepen regulatory engagement, and invest in supporting infrastructure such as vertiports and charging networks. This financial backing signals strong investor confidence in the scalability of electric propulsion and composite structures within the UAM market.

Looking ahead, the combined impact of advanced composite wing manufacturing and robust financing pipelines positions the eVTOL sector for rapid growth. Certification timelines targeting 2027 suggest that regulators like the FAA, EASA, and Brazil’s ANAC are adapting processes to accommodate novel aircraft configurations, while manufacturers benefit from reduced development risk through proven composite supply chains. As urban congestion intensifies, stakeholders—from airlines to city planners—will increasingly view eVTOLs as viable solutions for short‑haul mobility, making the current wave of partnerships and capital infusions a pivotal catalyst for industry-wide adoption.

North Aircraft Industries is manufacturing the Cavorite X7 VTOL composite wings

Published 02/18/2026 · Grace Stubbins · Senior Managing Editor, CompositesWorld and Products Finishing

New Horizon Aircraft Ltd. (Toronto, Canada) has formed a partnership with North Aircraft Industries (NAI, London, Canada) to manufacture and test the custom‑engineered wings for the company’s full‑scale vertical take‑off and landing (VTOL) aircraft, the Cavorite X7.

NAI is globally recognized for its expertise in complex aerospace composites engineering, manufacturing and testing. Its skilled engineering and production teams and composites technologies deliver lightweight, high‑strength aircraft components for faster, longer‑range and more efficient flight. Further differentiated by its in‑house structural testing capabilities, NAI will conduct wing structural testing upon manufacturing completion.

Learn to Cut the Cost and Time of Tooling

“The Cavorite X7’s design represents a genuinely new approach to VTOL aircraft performance and operational flexibility,” says Joost List, CEO of NAI. “It aligns with our strengths in advanced composite structures and integrated aerospace component development. We consider it a privilege to collaborate on a critical primary structure such as the wing.”

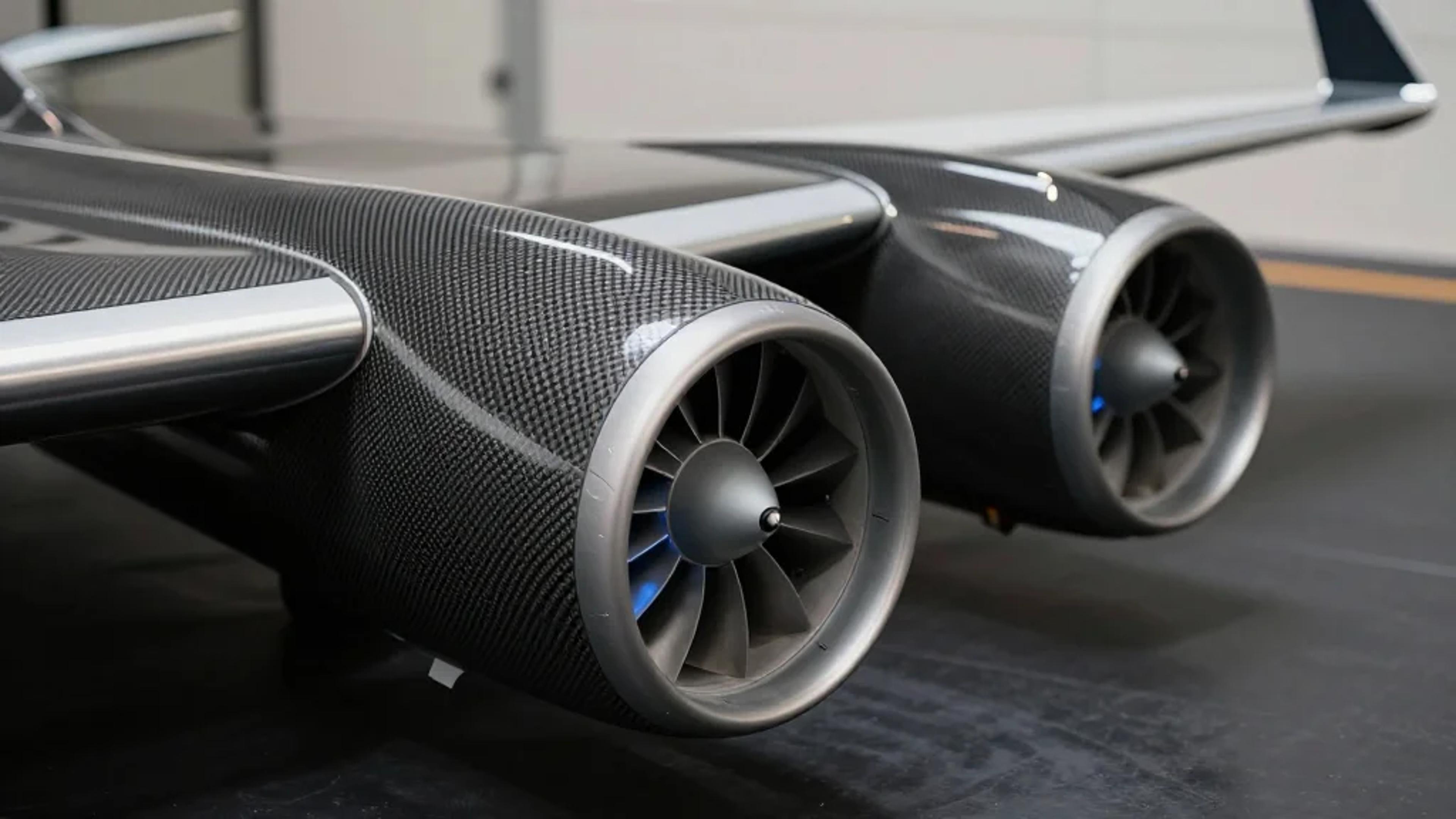

The VTOL’s novel wing architecture enables vertical take‑off and landing by opening wing covers to reveal twelve embedded electric lift fans. In forward flight the covers close, transforming the aircraft into an efficient fixed‑wing configuration.

This partnership follows an earlier agreement with RAMPF Composite Group, which will manufacture the prototype aircraft’s composite airframe.

Published 02/06/2026

Eve Air Mobility accelerates eVTOL development with flight, funding

Grace Stubbins – Senior Managing Editor, CompositesWorld and Products Finishing

Over the last couple of months Eve Air Mobility (São José dos Campos, Brazil) has announced two important milestones marking progress in the commercialization and development roadmap of its electric vertical take‑off and landing (eVTOL) aircraft.

Mid‑December 2025, Eve completed the first flight of its uncrewed full‑scale eVTOL prototype at Embraer’s test facility in Gavião Peixoto, Brazil. This inaugural flight initiated the company’s flight‑test phase and confirmed the integration of key systems, including a fifth‑generation fly‑by‑wire concept and fixed‑pitch lifter rotors, validating the aircraft’s overall architecture, controls and integrated propulsion.

“This flight validates our plan … we were able to capture high‑fidelity data that will allow us to move forward with safety and confidence towards the certification path,” says Johann Bordais, CEO of Eve Air Mobility.

Following this hover flight, Eve plans multiple flights in 2026 to expand the flight envelope and progress toward full wing‑borne flight as part of its test campaign.

Eve will manufacture six conforming prototypes for the flight‑test campaign aimed at achieving certification. The company continues to engage with Brazil’s Civil Aviation Agency (ANAC) and other regulators, including the U.S. Federal Aviation Administration (FAA) and the European Union Aviation Safety Agency (EASA), as it advances toward type certification, first deliveries and entry into service expected in 2027.

Based on 2024 supplier announcements, which include names like Aciturri and FACC, composites are expected to play a role in Eve’s final aircraft.

Complementing its technical progress, Eve has secured US $150 million in debt financing from a syndicate of financial institutions, including Itaú, Banco do Brasil, Citibank and Mitsubishi UFJ Financial Group. The five‑year financing underscores strong market confidence in Eve’s vision and long‑term strategy, enhancing the company’s liquidity and enabling acceleration of development, certification and commercialization efforts.

Proceeds will support ongoing R&D, integration of the eVTOL aircraft into a comprehensive urban air‑mobility ecosystem, strengthening partnerships with infrastructure providers and regulatory bodies, and scaling operations in key urban markets. With this transaction, Eve’s total funding reaches approximately US $1.2 billion, reaffirming its position as, in its own words, “one of the best‑capitalized companies in the emerging eVTOL market.”

0

Comments

Want to join the conversation?

Loading comments...