Trener Robotics Acteris Platform Brings Pre-Trained Physical AI Skills to Industrial Robots

•February 12, 2026

0

Why It Matters

By replacing line‑by‑line coding with AI‑driven skills, Acteris shortens deployment cycles and helps manufacturers address labor shortages and the growing demand for flexible automation.

Key Takeaways

- •$32M Series A funding brings total $38M capital

- •Acteris adds natural‑language AI skills to existing robots

- •Targets CNC machine tending; expands to other processes 2026

- •Compatible with ABB, Universal Robots, FANUC; 15+ partners

- •Flexible automation market growing 14.3% CAGR

Pulse Analysis

Industrial robotics has long been hampered by rigid, point‑to‑point programming that demands specialist engineers and extensive downtime for retooling. As manufacturers shift toward high‑mix, low‑volume production to stay competitive, the need for adaptable automation has intensified. Labor shortages and rising operational costs further pressure factories to extract more value from each robot, prompting a wave of AI‑centric solutions that promise to bridge the gap between human intuition and machine precision.

The Acteris platform tackles these challenges by embedding pre‑trained Physical AI models directly onto legacy robot hardware. Leveraging data harvested from human operators, robot telemetry, and process video, the system translates natural‑language commands into executable motion plans, handling part identification, collision avoidance, and dynamic motion optimization on the fly. Its agentic interface eliminates the steep learning curve of traditional robot programming, allowing shop‑floor staff to sequence tasks, run simulations, and monitor performance through real‑time dashboards. Compatibility with major brands such as ABB, Universal Robots and FANUC, plus a network of over 15 system integrators, accelerates adoption across diverse manufacturing environments.

With a 14.3% compound annual growth rate projected for flexible automation, Acteris arrives at a pivotal moment. The recent $32 million Series A injection not only validates investor confidence but also funds expansion into new verticals beyond CNC machine tending. As integrators package Acteris with grippers and sensors, the platform promises to convert bespoke automation projects into repeatable, scalable solutions, delivering faster time‑to‑value and more predictable ROI for manufacturers worldwide. This shift toward AI‑driven robot skills could redefine factory floor operations, setting a new standard for intelligent, conversational automation.

Trener Robotics Acteris Platform Brings Pre-Trained Physical AI Skills to Industrial Robots

Laura Davis · Editor‑in‑Chief, New Equipment Digest · Feb. 12, 2026

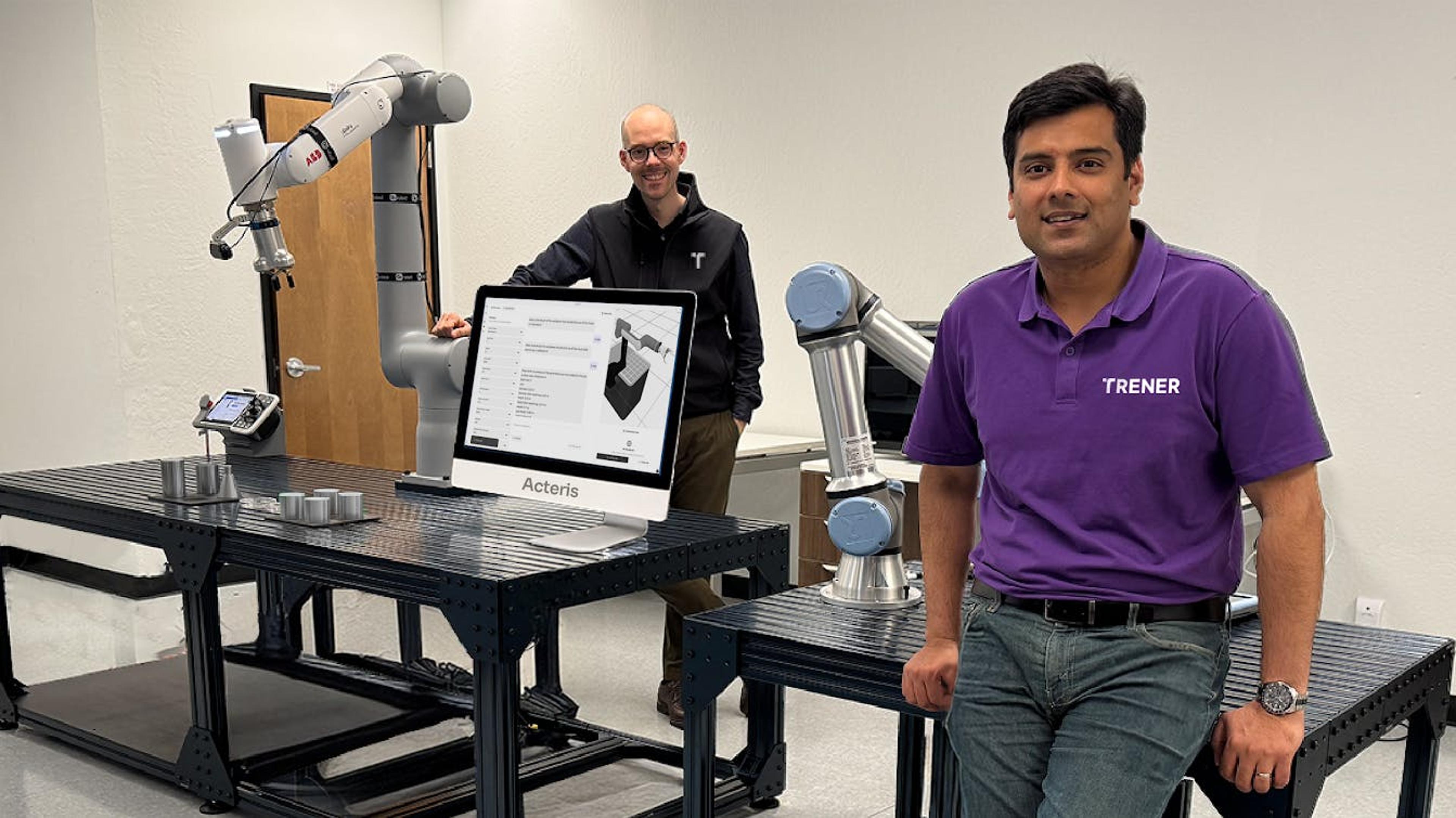

Trener Robotics is rolling out a new approach to industrial robot programming—replacing rigid, line‑by‑line coding with pre‑trained Physical AI skills designed for real‑world production environments.

Backed by a $32 million Series A round, the company’s Acteris platform layers software‑defined intelligence onto existing industrial robots, allowing operators to describe tasks in their own words and convert conversational input into executable automation. The funding, co‑led by Engine Ventures and IAG Capital Partners with participation from Cadence and Geodesic Capital through Nikon’s NFocus Fund, brings the company’s total funding to more than $38 million. The capital will support expansion into new markets, additional AI model training for new robot processes, and scaling its team.

Acteris Overview

Acteris is built to address a longstanding limitation in industrial robotics: most robots remain confined to repetitive, single‑purpose tasks in tightly controlled environments. Instead of procedural programming, Acteris embeds pre‑trained AI skills derived from data captured from humans, robots, and industrial process videos. The goal is to give robots the ability to adapt to high‑mix production without constant reprogramming.

“By replacing procedural programming with pre‑trained AI skills, we give robots the ability to understand and act with true intelligence learned from data extracted from humans, robots, and videos of industrial processes.”

— Dr. Asad Tirmizi, co‑founder and CEO of Trener Robotics

The platform’s first target application is robotic CNC machine tending, with additional applications planned for 2026.

For manufacturers, Acteris delivers:

-

A natural‑language, agentic user interface that allows operators to control robots through conversation, task sequencing, and simulation—without deep robotics expertise.

-

Part identification and handling, even in variable or adverse conditions.

-

Motion optimization that reacts to changes on the fly.

-

Collision avoidance and safety functions designed to mimic human‑like judgment.

-

Real‑time production dashboards for performance tracking.

The company is also positioning Acteris as a scalability tool for system integrators. More than 15 integration partners across the U.S. and Europe are offering turnkey Acteris‑powered systems that bundle robot, gripper, and software into pre‑integrated packages. The platform is currently compatible with ABB, Universal Robots, and FANUC robots, with additional brands planned.

By standardizing robot and application logic, Acteris aims to reduce programming time, shorten deployment cycles, and convert custom, one‑off automation projects into repeatable solutions. For integrators, that translates into faster project timelines and more predictable outcomes; for end users, it means a more modern operator experience and quicker time to value.

The market for flexible automation continues to climb, growing at a 14.3 % CAGR, driven by labor shortages, rising operating costs, and the need to support high‑mix production. Trener Robotics has already drawn interest from machine‑tool OEMs and hardware manufacturers exploring embedded AI‑driven automation.

Recent recognition includes the Machine Tool Innovation Award at EMO Hannover and selection as a winner in the ABB AI Startup Challenge for advancements in natural language programming, skill learning, and autonomous decision‑making.

With Acteris, Trener Robotics is betting that pre‑trained AI skill models—rather than traditional programming—will define the next generation of robot operations on the factory floor.

About the Author

Laura Davis – Editor‑in‑Chief, New Equipment Digest

Email: [email protected]

Laura Davis leads New Equipment Digest, a brand of the Manufacturing Group at EndeavorB2B. She covers a broad range of manufacturing products, equipment, solutions, and technologies, drawing on eight years of experience as a manufacturing product writer.

0

Comments

Want to join the conversation?

Loading comments...