Weaving Flexibility Into Nitinol: IMDEA–UPM Advances 3D Printed Superelastic Metamaterials

•February 18, 2026

0

Weaving Flexibility into Nitinol: IMDEA–UPM Advances 3D Printed Superelastic Metamaterials

Paloma Duran

Paloma Duran holds a BA in International Relations and an MA in Journalism. Specializing in writing, podcasting, and content and event creation, she works across politics, energy, mining, and technology. With a passion for global trends, Paloma is particularly interested in the impact of technology like 3D printing on shaping our future.

No Newer Articles

Researchers from IMDEA Materials Institute and the Technical University of Madrid (UPM) have reimagined nickel-titanium (Nitinol) alloys as fabric-like, interwoven structures, achieving levels of flexibility and mechanical performance previously impossible. By combining design-focused approaches with advanced 3D printing, the team has created superelastic metamaterials that could transform applications in robotics, aerospace, and healthcare.

The project, published in Virtual and Physical Prototyping, involved Carlos Aguilar Vega, Andrés Díaz Lantadam, Óscar Contreras, Dr. Muzi Li, Dr. Vanesa Martínez, Amalia San Román, Prof. Jon Molina, and Rodrigo Zapata Martínez, with support from the iMPLANTS-CM initiative funded by the Comunidad Autónoma de Madrid.

Addressing Limitations of 3D Printed Nitinol

Nickel–titanium (Nitinol) alloys are renowned for their superelasticity and shape-memory properties. Although laser powder bed fusion (LPBF) is widely employed for 3D printing Nitinol, the technique has traditionally resulted in reduced elasticity and lower recoverable strain compared with conventionally processed material.

“While LPBF remains the gold standard of nitinol additive manufacturing, the shape-memory and superelastic properties of these additively manufactured NiTi parts do not yet match those achieved with more conventional industrial processes,” says Carlos Aguilar Vega, researcher from IMDEA Materials and the UPM.

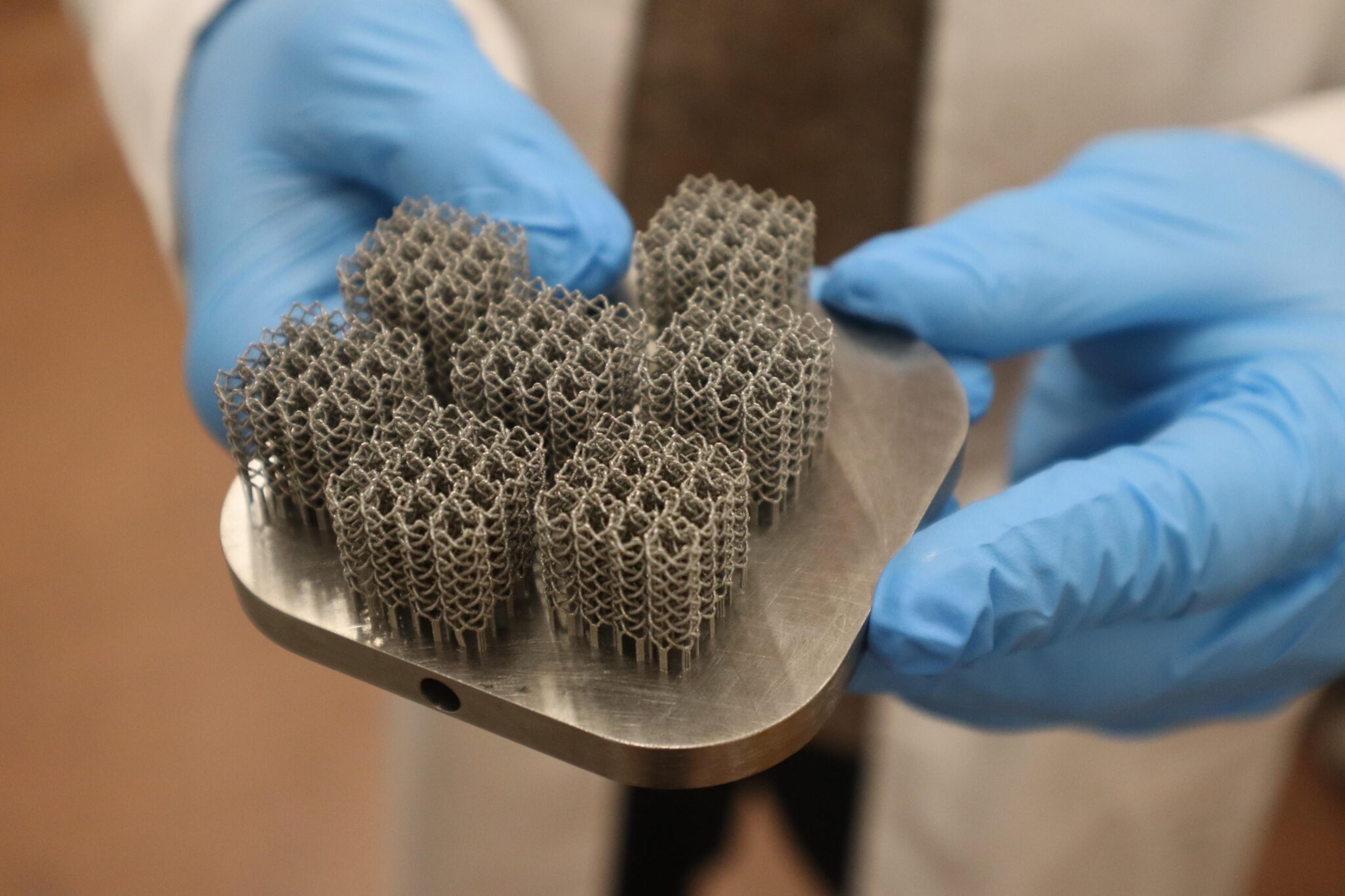

Architected 3D printed superelastic nitinol lattices. Photo via IMDEA Materials Institute.

Earlier research has indicated that 3D printed Nitinol exhibits approximately half the deformability of conventionally manufactured industrial Nitinol, with the additive processing of powders tending to produce materials with increased brittleness.

To overcome this, the team shifted from optimizing material composition to designing geometries that enhance mechanical performance, including intricate woven forms like meshes, spheres, and rings. “These were some of the most complex-shaped woven nitinol structures ever created”, explains fellow author, Prof. Andrés Díaz Lantada from the UPM and IMDEA Materials Institute.

Design-Based Framework for High-Performance Metamaterials

The researchers developed an algorithmic framework to create highly deformable, interwoven metamaterials tailored for additive manufacturing. Two main structure families—tubular lattices and cylindrical woven architectures—were produced and rigorously tested.

Mechanical testing confirmed that stiffness, load-bearing capacity, energy absorption, and toughness could be tuned through design alone. To ensure precision, the team used computed tomography alongside digital 3D printing models, validating the accuracy of complex geometries.

“This work represents the first demonstration of design-based optimisation of additively manufactured superelastic nitinol, showing that mechanical drawbacks inherent to current additive manufacturing processes can be effectively mitigated through architecture,” concludes Vega.

Designing Around the Core Constraint in 3D Printed Nitinol

The central challenge in additively manufactured Nitinol is not geometry, but functional consistency. While LPBF enables complex forms, maintaining stable transformation behavior during processing remains difficult due to the alloy’s narrow compositional tolerance and thermal sensitivity. The result has been variability in performance compared with conventionally produced material.

Many industry efforts have therefore focused on process stabilization, including tighter atmospheric control and refined printing parameters to reduce chemical drift and structural anisotropy. For example, Linde has implemented gas management systems to regulate oxygen levels during metal AM.

Discoloration occuring on nitinol parts when oxygen levels are not strictly controlled. Image via Linde.

Despite these challenges, functional Nitinol parts can still be realized. A notable case is a deployable aerospace NiTi structure produced via DMP technology, where a printed actuator enabled passive deployment with an increase in surface area and reduced weight.

The IMDEA–UPM study takes a different approach. Instead of focusing on material optimization alone, it leverages architected geometries to compensate, demonstrating that mechanical performance can be tuned through design.

Despite the improvements, key limitations remain in 3D printed Nitinol. Its superelastic and shape-memory behavior remains highly sensitive to nickel content, oxygen exposure, and thermal history, leading to variability in performance compared with conventionally processed material. LPBF can introduce microstructural anisotropy and residual stresses that cannot be fully corrected by geometry alone. Additionally, the complexity of woven or interwoven architectures presents practical challenges for large-scale or mass production.

The3D Printing Industry Awardsare back. Make your nominations now.

Do you operate a 3D printing start-up? Reach readers, potential investors, and customers with the3D Printing Industry Start-up of Yearcompetition.

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the3D Printing Industry newsletteror follow us onLinkedin.

Featured image shows Architected 3D printed superelastic nitinol lattices. Photo via IMDEA Materials Institute.

0

Comments

Want to join the conversation?

Loading comments...