How a Solar Impulse Spinoff Cleared a Major Battery Certification Hurdle

•February 3, 2026

0

Why It Matters

EASA certification removes a key safety barrier, accelerating the commercial rollout of electric‑propulsion aircraft and boosting investor confidence in the emerging market.

Key Takeaways

- •H55 completed EASA‑witnessed full battery certification test.

- •Test validates safety of large aviation propulsion batteries.

- •Certification paves way for cert‑ready battery modules to customers.

- •Demonstrates regulator‑manufacturer alignment on test requirements.

- •Boosts confidence for electric and hybrid‑electric aircraft market.

Pulse Analysis

Thermal runaway has long haunted electric‑aircraft developers, with safety regulators demanding proof that thousands of lithium cells can coexist without igniting at altitude. Traditional automotive certifications fall short for aviation, where emergency landings are far more complex. H55, born from the Solar Impulse project, tackled this gap by engineering a battery architecture that integrates advanced thermal management, cell‑level monitoring, and redundant safety circuits, all built on a production‑line that mirrors aerospace quality standards.

The certification sequence, overseen by EASA, subjected the battery packs to a battery of stress tests: over‑temperature exposure, vibration, altitude simulation, and fault‑induced fire scenarios. Each test replicated worst‑case conditions an aircraft might encounter, and the successful outcomes demonstrated that the packs can contain and extinguish thermal events without compromising structural integrity. Crucially, the approval was granted on units produced directly from H55’s manufacturing line, confirming that the design’s safety is reproducible at scale, not just a laboratory prototype.

Industry observers view H55’s achievement as a catalyst for the electric‑aircraft ecosystem. With a certified power source, aircraft manufacturers can now advance designs from concept to type‑certificate without awaiting bespoke battery approvals. This reduces development timelines, lowers capital risk, and encourages supply‑chain investment in high‑energy, lightweight cells. Moreover, the regulatory precedent set by EASA may streamline future certifications, prompting other battery innovators to adopt similar test frameworks and hastening the broader transition to zero‑emission aviation.

How a Solar Impulse spinoff cleared a major battery certification hurdle

When skeptics of electric aircraft enumerate the reasons why these designs will never succeed, thermal runaway is usually somewhere high on the list. The risk posed by hundreds or thousands of lithium battery cells overheating into failure might be acceptable in a ground vehicle, where the driver can quickly pull over and get out if the battery catches on fire. Not so in an aircraft, these skeptics maintain, given that emergency landings are rarely so straightforward.

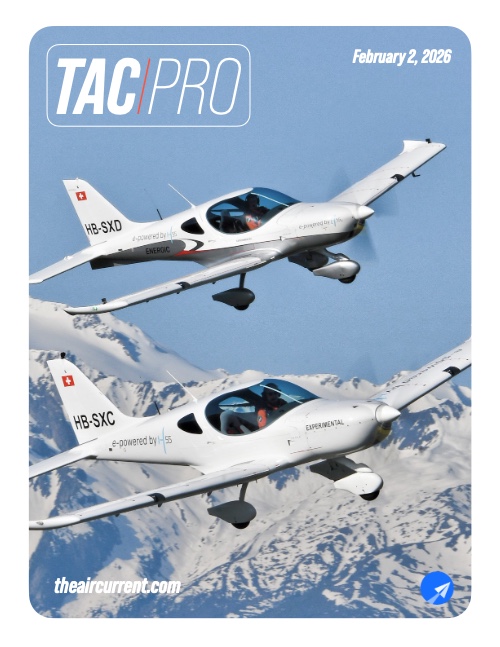

Developers of certifiable batteries for electric aircraft don’t claim the process is easy, but they deny that it is impossible. An important proof point came on Feb. 2 from Swiss startup H55, which is developing energy storage systems for a variety of electric and hybrid‑electric airplanes. The company announced it successfully completed a full certification test sequence for its high‑energy propulsion batteries, which was approved and witnessed by the European Union Aviation Safety Agency.

The milestone is an important one for the company, demonstrating the maturity of its battery design and production line. It also has broader significance for the industry as an example of a regulator and manufacturer agreeing on the tests required to demonstrate that a large aviation propulsion battery is safe for flight.

“I think we have really a safe solution here and now it’s been tested … on products which are produced by the production line,” H55 co‑founder and executive chairman André Borschberg said in an interview with The Air Current. With H55 now poised to deliver certification‑ready battery modules to its customers, he added, “we hope that this will help to accelerate the commercialization of electric‑based aircraft.”

0

Comments

Want to join the conversation?

Loading comments...