Alloyed Secures £1 Million to Develop Next‑gen Nickel‑based Superalloy for 3D‑printed Jet Engine Parts

•February 19, 2026

0

Participants

Why It Matters

The upgraded superalloy could enable lighter, more efficient jet engines, accelerating adoption of 3D‑printed aerospace components. Success would also showcase the value of public‑private funding in fast‑tracking advanced manufacturing technologies.

Key Takeaways

- •£1 million ATI funding secured for alloy development

- •ABD‑1000AM targeted for laser powder bed fusion jet parts

- •Cranfield to develop oxidation‑resistant coating for alloy

- •ITP Aero contributes combustor expertise to project

Pulse Analysis

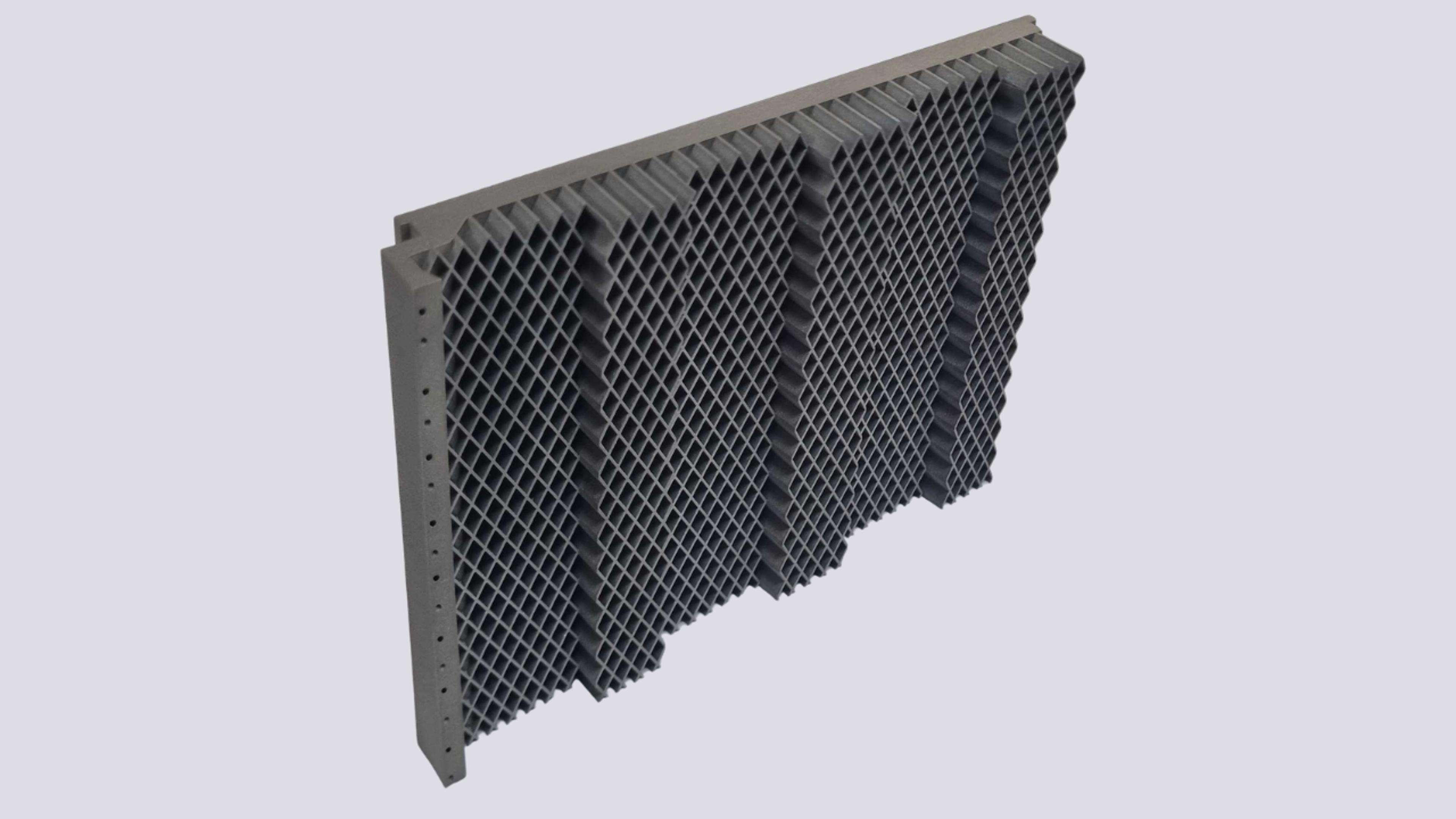

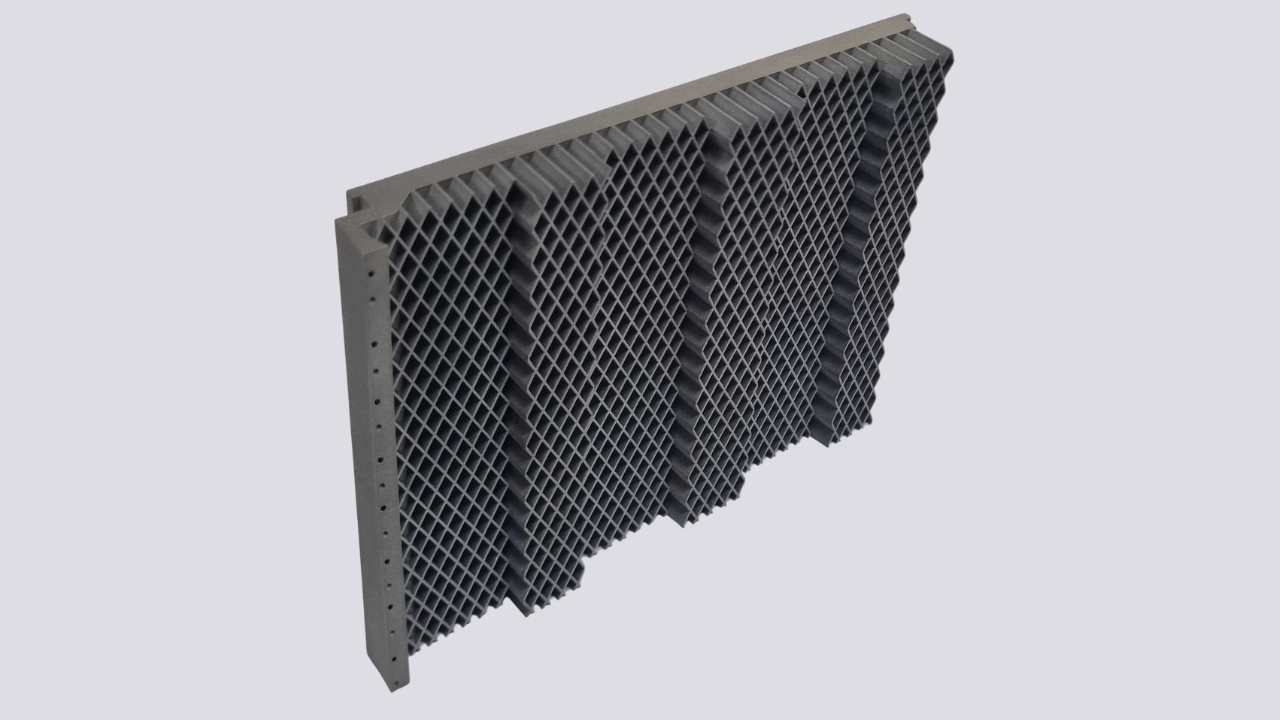

Additive manufacturing is reshaping aerospace engineering, but the technology hinges on materials that can survive extreme temperatures and stresses. Nickel‑based superalloys have long been the workhorse of turbine blades, yet traditional casting methods limit design freedom. Alloyed’s Alloys‑by‑Design platform leverages computational thermodynamics to tailor chemistry and microstructure, delivering ABD‑1000AM—a high‑temperature alloy optimized for laser powder‑bed fusion. By marrying data‑driven alloy design with 3D printing, the company addresses a critical bottleneck: producing intricate, weight‑saving components without compromising durability.

The £1 million ATI‑backed project brings together ITP Aero’s combustor expertise and Cranfield University’s surface‑engineering capabilities. Cranfield’s National High Temperature Surface Engineering Centre will formulate a protective coating that mitigates oxidation, extending the alloy’s service life in the harsh environment of jet engines. Simultaneously, ITP Aero will integrate the material into next‑generation combustor designs, accelerating the path from laboratory to flight‑ready parts. This collaborative model also aligns with broader industry efforts to streamline certification; the same funding stream supports a £14 million digital qualification platform that could simplify regulatory approval for 3D‑printed components.

If successful, ABD‑1000AM could become a cornerstone for ultra‑efficient propulsion systems, offering manufacturers a route to lighter, more fuel‑efficient engines. The project underscores how targeted public investment can de‑risk high‑tech development, fostering rapid commercialization of advanced materials. As airlines pursue carbon‑neutral goals, the demand for high‑performance, additively manufactured turbine components is set to surge, positioning Alloyed and its partners at the forefront of the next aerospace materials revolution.

Deal Summary

Alloyed announced it has secured £1 million in funding from the ATI Programme to develop a next‑generation nickel‑based superalloy for additive manufacturing of jet engine components. The project, which also involves ITP Aero and Cranfield University, aims to enhance the high‑temperature alloy ABD‑1000AM for future aerospace engines.

Article

Source: TCT Magazine

Alloyed has announced it has received funding from the ATI Programme towards an ambitious £1 million project focused on the development of a next-generation nickel-based superalloy for additive manufacturing.

The project, which also includes ITP Aero and Cranfield University, aims to enhance the capabilities of ‘ABD-1000AM’, a high-temperature alloy designed for laser powder bed fusion, which is thought to be vital to the production of ultra-efficient future jet engines. Launched in 2024 in partnership with Aubert & Duval, ABD-1000AM was developed using Alloyed’s computational Alloys-by-Design platform.

In a press release, Alloyed said it has identified "huge demand" for the material, particularly as next-generation aerospace components require more intricate geometries made from materials capable of surviving the high temperatures and harsh conditions of combustion. The company, which specialises in the computational design and optimisation of metallic materials, believes the material will be "game changing" for building gas turbines for aerospace propulsion and industrial power generation.

A team at Cranfield University's National High Temperature Surface Engineering Centre will be applying its expertise in coatings capable of withstanding oxidation and high temperatures to the development of a protective coating tailored for the ABD-1000AM. The ITP Aero UK team will provide technical knowledge and experience in developing combustor technology.

Dr David Crudden, Chief Metallurgist and Head of New Market Development at Alloyed, described the project as a prime example of how ATI funding is being used to "bridge the gap between early research and industry development programs."

Rob Mitchell, Director of Engineering for ITP Aero UK, said: “We look forward to working together to discover how this advancement can make a real-life difference to our industry, the technology we are developing today, and the future projects we are focused on for the pioneers of tomorrow.”

This project is one of several ongoing collaborations between Alloyed and the ATI Programme, including the development of a high-strength aluminium alloy for aerospace applications and a £14 million initiative focused on a digital qualification platform to streamline the certification process for flight-ready 3D printed components.

0

Comments

Want to join the conversation?

Loading comments...