How Airbus Is Pioneering Aircraft Manufacturing with Titanium 3D Printing

•February 10, 2026

0

Why It Matters

w‑DED slashes titanium waste and tooling costs while accelerating aircraft development, giving Airbus a competitive edge in lightweight, cost‑effective airframe production.

Key Takeaways

- •w-DED prints up to 7‑meter titanium parts

- •Material waste reduced, buy‑to‑fly ratio improves

- •Production speed rises to kilograms per hour

- •Lead time drops from years to weeks

- •Enables single‑piece designs, simplifying supply chain

Pulse Analysis

Additive manufacturing has moved beyond small‑scale aerospace parts, and Airbus’s wire‑Directed Energy Deposition (w‑DED) marks a decisive shift toward industrial‑grade 3D printing. Unlike powder‑bed systems limited to two‑foot components, w‑DED deposits molten titanium wire layer by layer using a robotic arm, allowing parts as long as seven metres. The process blends the precision of laser, plasma or electron‑beam energy sources with near‑net‑shape building, so only a brief machining step is needed to achieve final tolerances. This scalability bridges the gap between prototyping and full‑scale production, positioning w‑DED as a viable alternative to traditional forging.

The economic and environmental implications are equally compelling. Titanium’s high cost and the historically poor buy‑to‑fly ratios—often requiring 80‑95% material recycling—have long constrained aerospace budgets. By growing components directly to near‑final geometry, w‑DED dramatically cuts raw‑material waste, improving the buy‑to‑fly metric and lowering material spend. Faster build rates, measured in kilograms per hour, translate to shorter production cycles and reduced inventory. Moreover, the ability to design parts for DED—consolidating multiple assemblies into a single printed piece—simplifies the supply chain, trims assembly labor, and enhances overall aircraft weight efficiency.

Strategically, Airbus is already embedding w‑DED parts into the A350 cargo‑door‑surround, demonstrating functional parity with forged equivalents while delivering cost savings. The technology’s agility, shrinking tooling lead times from years to weeks, accelerates design iteration and supports rapid program adjustments. As Airbus evaluates in‑house versus outsourced printing and standardizes the process across its portfolio, competitors are racing to adopt similar capabilities. The broader industry impact could reshape aircraft manufacturing economics, drive broader adoption of titanium‑rich designs, and set a new benchmark for sustainable, high‑volume aerospace production.

How Airbus is pioneering aircraft manufacturing with Titanium 3D printing

Wire‑Directed Energy Deposition (w‑DED): Airbus’s New 3D‑Printing Technique for Large Structural Parts

Picture an aircraft industry where the toughest structural components of an airliner – parts that handle stress and fatigue – are grown from a spool of wire, rather than being carved out of blocks of metal as is the norm today. In fact that’s starting to become a reality in Airbus’ factories as they prepare for the future.

The technology in question is a 3D printing technique called wire‑Directed Energy Deposition (w‑DED). This uses a new additive manufacturing approach with titanium to create structural aircraft parts with less resulting material waste, compared with the traditional subtractive methods such as machining from plate or forging.

How does w‑DED work?

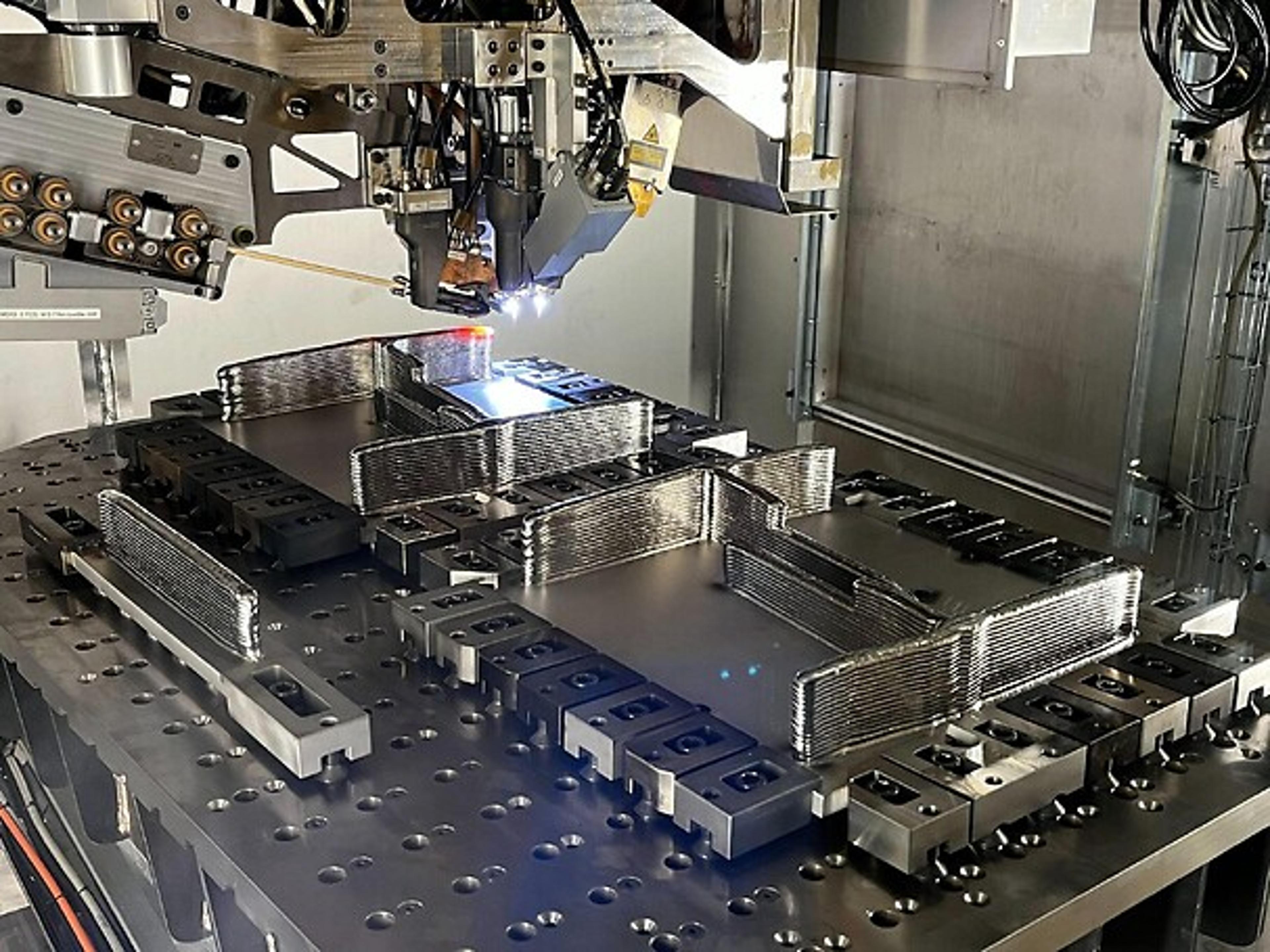

The technique uses a multi‑axis robotic arm, armed with a spool of titanium wire, moving with digital precision. Energy, in the form of a laser, plasma, or electron beam is focused onto the wire, instantly melting it and fusing it layer‑by‑layer onto a surface. Superficially similar to welding, but with a 3D model as its guide, it prints the object from the ‘ground up’ into what is known as a ‘blank’. This blank looks very much like the final required shape, i.e. ‘near net shaped’, which subsequently undergoes a quick machining to conform to the exact dimensions of the part design.

w‑DED: unlocking 3D printing for large parts

While 3D printing with metals in aerospace has been used for around a decade, up until now it has mostly been used for smaller components. These conventional systems, called ‘powder‑bed’ printers, were typically optimised for making parts that are less than two feet long.

w‑DED, on the other hand, allows Airbus to move from printing small components to creating large, structural titanium parts up to seven meters (over 23 feet) long. The new process promises to be faster than powder‑bed 3D printing, boosting production from hundreds of grammes per hour to several kilogrammes per hour. This leap could make 3D printing viable for industrial, high‑volume manufacturing of large structural components for commercial aircraft.

Helping to reduce titanium raw material waste

Why focus on titanium? While the metal is essential for aircraft due to its strength, lightness and compatibility with modern carbon‑fibre composite structures (such as corrosion resistance, relative expansion coefficients and other properties), titanium is also a high‑value raw material, so conserving it is paramount.

Consider that traditional forging – i.e. machining a part from a solid block – creates a high proportion of raw material ‘waste’. This is measured by the ‘buy‑to‑fly’ ratio – the amount of raw material purchased versus the amount that actually ‘flies’ in the aircraft. In traditional methods, one might need to recycle between 80 % and 95 % of the titanium originally bought.

With w‑DED, such waste is mostly prevented at source. This is because the part is ‘grown’ into a shape that is already very close to the final design (a ‘near net shape’), leaving very little material to machine away.

Bringing agility to aircraft development

Traditional die forging also requires the creation of large, complex tooling that can take up to two years and require a large up‑front capital investment. By contrast, a 3D‑printed part’s shape is determined by a computer programme, reducing the lead time to just a few weeks. w‑DED’s agility will be of immediate benefit to the successful and timely construction of the first development aircraft, especially while the final detailed component designs are being tweaked and optimised, right up to the point when the first aircraft starts to take physical shape.

First proof in A350 production

Airbus has recently started serial integration of the largest w‑DED parts into the A350’s cargo‑door‑surround area. These particular Airbus‑designed parts for this exploratory phase were 3D‑printed by a qualified supplier using plasma w‑DED, ultrasonically inspected by Testia Bremen and finally machined and installed in Airbus factories.

These parts are functionally and geometrically identical to the traditional forged components they replace, but they deliver immediate, real‑world cost savings. Looking forward, the next aim is to progress, step by step, from the A350 w‑DED parts into more critical applications on other programmes and other aircraft (including the wings and landing gear in the longer term).

“Designed for DED”

Importantly, this technology enables a concept called “designed for DED.” Instead of having engineers design a complex component as an assembly of several separate pieces that must be joined together, they can now design it as a single, intricate and optimised component that is printed all at once. This ability to merge multiple components into one will simplify the supply chain, reduce assembly labour, shorten cycle time and unlock the full potential of the next generation of 3D‑designed airliners.

The race is on…

Today in Airbus and its partners the race to accumulate experience of w‑DED for critical parts is well underway, with very promising success. Engineers are testing various energy sources, including plasma, arc welding, electron‑ and laser beam, and simultaneously evaluating “Buy” (outsourcing the printing) and “Make” (doing it in‑house) strategies. Moreover, being governed as an Airbus‑group‑level approach, the resulting technologies will become an industrial standard and be usable across the company.

0

Comments

Want to join the conversation?

Loading comments...