Why It Matters

The accelerated progress boosts Europe’s renewable capacity, enhancing energy security and supporting the continent’s decarbonisation targets. It also signals robust financial confidence for large‑scale offshore wind investments.

Key Takeaways

- •EEW and CS Wind delivered monopiles ahead of schedule

- •68 monopiles and transition pieces prepared for installation

- •Nordlicht I contributes 980 MW, Germany's largest offshore wind

- •Cluster delivers 1.6 GW, roughly 6 TWh yearly output

- •Early component delivery speeds up offshore construction timeline

Pulse Analysis

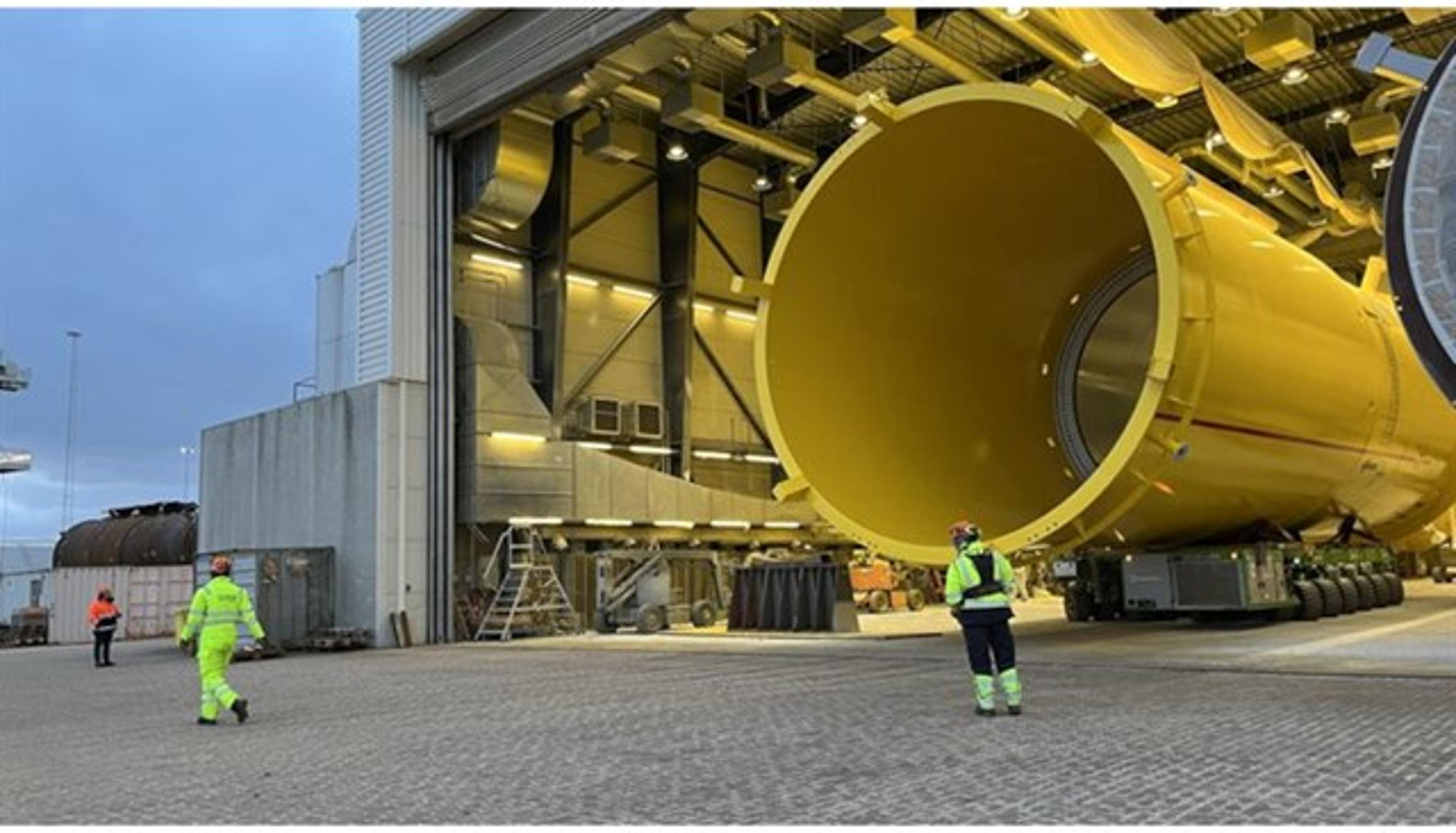

The swift fabrication of Nordlicht I’s monopiles and transition pieces underscores a maturing offshore‑wind supply chain in Europe. EEW and CS Wind completed 68 steel structures—80.5 metre monopiles weighing up to 1,290 tonnes and 23.7 metre transition pieces at roughly 362 tonnes—well before the slated installation window. By front‑loading these heavy‑lift components, the project mitigates logistical bottlenecks that often delay offshore construction, allowing the turbine‑erection phase to commence on schedule later this year. Early delivery also signals robust coordination between the developer and tier‑one manufacturers, a model other developers are keen to emulate.

At 980 MW, Nordlicht I will become Germany’s largest offshore wind farm, while the combined Nordlicht I and II cluster pushes total capacity beyond 1.6 GW and an estimated 6 TWh of annual generation. This output aligns with Germany’s 2030 offshore wind target of 20 GW and the EU’s broader ambition to achieve climate neutrality by 2050. By delivering fossil‑free electricity at scale, the project strengthens European energy security, reduces reliance on imported gas, and provides a clean power source for industrial decarbonisation initiatives.

The early milestone also validates Vattenfall’s recent final investment decision and the binding permit for Nordlicht II, signaling confidence in the financial viability of large‑scale offshore assets. Investors are watching the project’s progress as a barometer for future capital allocation toward the North Sea corridor, where turbine sizes and hub heights are rapidly increasing. Moreover, the demand for high‑specification monopiles and transition pieces is spurring innovation among European fabricators, potentially lowering costs through economies of scale. As more clusters reach commercial operation, the offshore wind sector is poised to become a cornerstone of Europe’s power mix.

Nordlicht I components completed early

EEW and CS Wind deliver first foundations · 19 February 2026

The Nordlicht cluster has reached a key milestone with the early completion of the first monopiles and transition pieces for Nordlicht I. The components were manufactured by EEW and CS Wind ahead of schedule, said the project team. The early delivery reflects effective collaboration with suppliers and marks a significant advance before offshore construction begins later this year, added the developer.

“Nordlicht is not simply another offshore wind project – it is a key building block of the future European energy system. By providing over 1.6 GW of fossil‑free capacity, Nordlicht strengthens Europe’s competitiveness, reduces dependence on fossil fuels, and enables industry to decarbonise on a large scale.”

— Jonas van Mansfeld, acting head of BU offshore

The monopiles measure up to 80.5 metres in length and weigh up to 1 290 tonnes, while the transition pieces reach 23.7 metres in height and weigh around 362 tonnes. A total of 68 monopiles and transition pieces will be installed for Nordlicht I.

Nordlicht I is expected to become Germany’s largest offshore wind farm once operational in less than three years. The development of the Nordlicht cluster has accelerated following the binding permit for Nordlicht II and Vattenfall’s final investment decision in January.

The cluster consists of:

-

Nordlicht I – 980 MW

-

Nordlicht II – 630 MW

Together they deliver more than 1.6 GW in total. At full operation, the two farms are expected to produce around 6 TWh of electricity annually.

0

Comments

Want to join the conversation?

Loading comments...