Single-Atom Catalyst Produces Hydrogen and Oxygen Simultaneously, Slashing Costs

•February 20, 2026

0

Why It Matters

By slashing iridium usage and simplifying electrode architecture, the technology dramatically lowers capital and operating costs, accelerating the commercial rollout of electro‑lysis‑based green hydrogen.

Key Takeaways

- •Single‑atom Ir catalyst drives HER and OER simultaneously

- •Iridium usage cut to 1.5% of traditional catalysts

- •Binder‑free electrode boosts conductivity and durability

- •Stable performance over 300 hours in AEM electrolyzer

- •Potential to lower green hydrogen production costs dramatically

Pulse Analysis

The emergence of single‑atom catalysts marks a paradigm shift in electrocatalysis, where each metal atom becomes an isolated active site rather than part of a bulk particle. KIST’s approach leverages phytic‑acid‑mediated anchoring to lock iridium atoms onto a Mn‑Ni layered double hydroxide matrix, creating a bifunctional surface that simultaneously lowers the overpotential for HER and enhances OER kinetics. This atomic‑scale engineering reduces iridium demand by 98.5%, addressing one of the most prohibitive cost drivers in current water‑splitting technologies.

Beyond material savings, the binder‑free electrode architecture eliminates insulating polymer layers that traditionally impair electron transport and cause catalyst detachment during long‑term operation. Direct growth of the catalyst onto the electrode substrate yields a highly conductive interface and maintains structural integrity for more than 300 hours of continuous AEM electrolysis. The resulting durability and simplified stack design lower both capital expenditures (CAPEX) and maintenance overhead, making modular, high‑efficiency electrolyzers more economically viable for industrial deployment.

Global demand for green hydrogen is projected to exceed 500 million tonnes by 2050, yet high production costs remain a critical barrier. By cutting precious‑metal usage and streamlining cell construction, KIST’s single‑atom catalyst could reduce electrolyzer CAPEX by up to 30% and improve overall energy efficiency. This cost compression aligns with emerging policy incentives and renewable‑energy integration strategies, positioning the technology as a catalyst for rapid market adoption. Continued scale‑up studies and pilot‑plant demonstrations will be essential to validate performance under commercial conditions, but the underlying chemistry offers a compelling route to affordable, carbon‑free hydrogen at scale.

Single-atom catalyst produces hydrogen and oxygen simultaneously, slashing costs

Feb 20, 2026 · Nanowerk News

Green hydrogen production technology, which utilizes renewable energy to produce eco‑friendly hydrogen without carbon emissions, is gaining attention as a core technology for addressing global warming. Green hydrogen is produced through electrolysis, a process that separates hydrogen and oxygen by applying electrical energy to water, requiring low‑cost, high‑efficiency, high‑performance catalysts.

The Korea Institute of Science and Technology (KIST) announced that a research team led by Dr. Na Jongbeom and Dr. Kim Jong Min from the Center for Extreme Materials Research has developed next‑generation water electrolysis catalyst technology (Advanced Energy Materials, “Tailored Design of Iridium Single Atoms on Mn–Ni‑Phytate with Robust Bifunctionality for Enhanced Anion Exchange Membrane Water Electrolysis” – https://dx.doi.org/doi:10.1002/aenm.202506645).

This technology integrates a single‑atom “All‑in‑one” catalyst precisely controlled down to the atomic level with binder‑free electrode technology. A key feature is its ability to stably perform both hydrogen evolution and oxygen evolution reactions simultaneously on a single electrode.

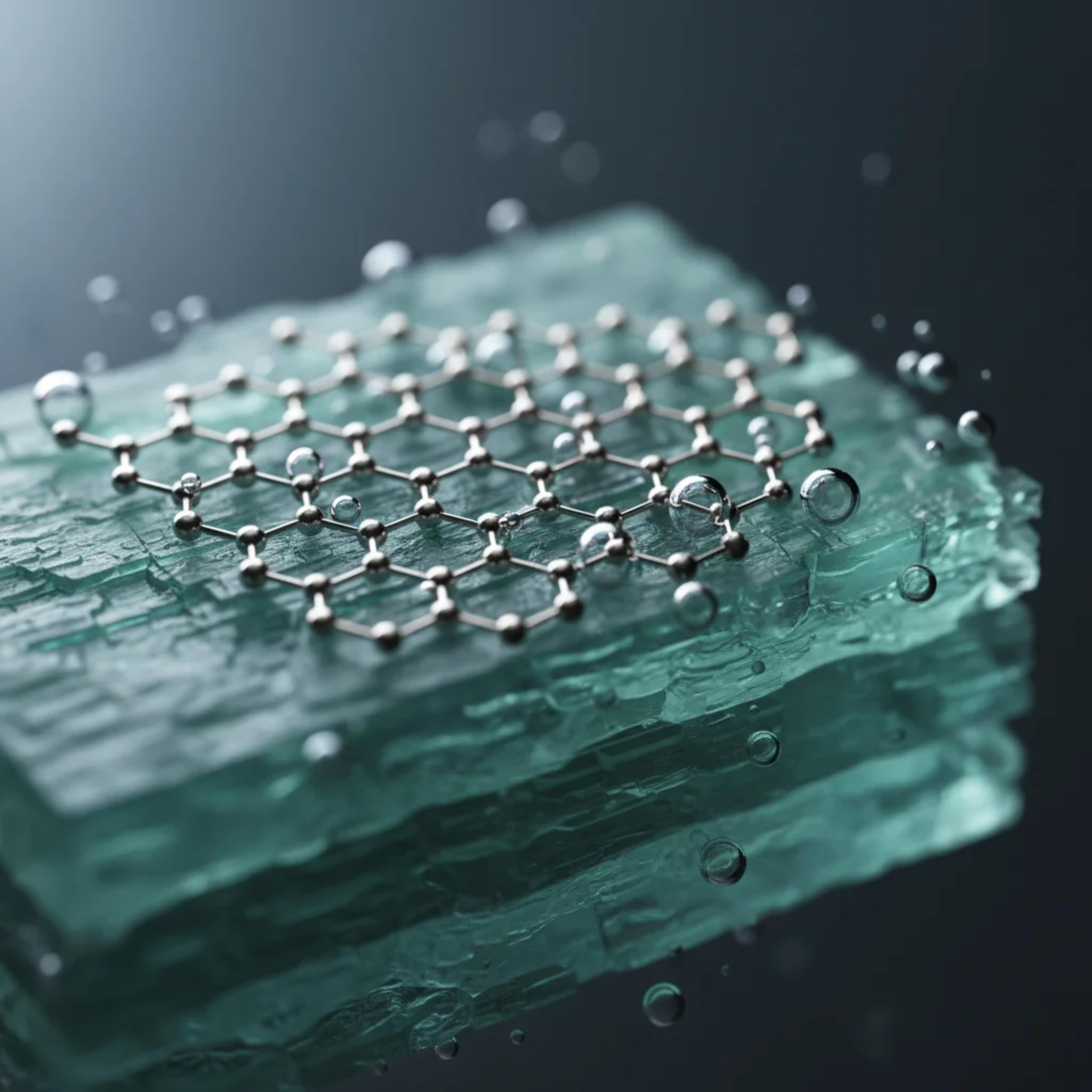

Image: Schematic illustration of single‑atom catalyst synthesis based on atomic‑level precision control technology

The schematic shows the fabrication of a single‑atom catalyst by introducing a molecular anchoring agent (phytic acid) into a manganese (Mn)‑nickel (Ni) layered double hydroxide (LDH) framework, enabling uniform immobilization of iridium (Ir) at the atomic scale. The engineered single‑atom hosting sites disperse iridium atoms, creating an “All‑in‑one” anion exchange membrane (AEM) water‑electrolysis catalyst capable of simultaneously driving both the hydrogen evolution reaction (HER) and the oxygen evolution reaction (OER) with a single catalyst. (Image: Korea Institute of Science and Technology)

Existing electrolysis systems required different catalysts and electrode structures for HER and OER, demanding large quantities of expensive precious metals. Moreover, binders used to fix the catalyst to the electrode reduced electrical conductivity and caused catalyst detachment during long‑term operation.

KIST researchers used atomic‑level precision control to uniformly disperse iridium atoms across the surface of a manganese‑nickel‑based LDH support incorporating phytic acid. This strategy replaces the conventional use of bulk iridium. By maximizing the number of active sites for water‑splitting reactions with minimal iridium, the approach is analogous to evenly spreading fine grains of sand over a large surface rather than relying on a single large rock.

In particular, the iridium single atom acts as a direct active site for HER through its strong interaction with the support, while simultaneously enhancing the catalytic performance of the nickel‑based active site where OER occurs. Thus, the single‑atom catalyst exhibits bifunctional catalytic characteristics suitable for both reactions.

Furthermore, the team applied a method of directly growing the catalyst on the electrode surface, creating an electrode structure that does not require a separate binder. This significantly improves electrical conductivity and ensures excellent durability even during long‑term operation.

The technology reduces precious‑metal usage to within 1.5 % of that required by existing catalysts while achieving outstanding performance in both hydrogen and oxygen evolution reactions. It also demonstrates high stability, with minimal performance degradation after continuous operation for over 300 hours in an AEM water‑electrolysis system.

These results demonstrate the technical feasibility of simultaneously enhancing the economic viability and durability of electrolysis systems by minimizing precious‑metal usage and simplifying electrode structures. The advance is expected to significantly contribute to the commercialization of green hydrogen production and to lower hydrogen‑production costs in the future.

Dr. Na Jongbeom of KIST stated, “This work is highly significant as it resolves the two essential reactions for hydrogen production using a single catalyst while reducing precious‑metal consumption.” He added, “This technology will accelerate the commercialization of water‑electrolysis devices and provide substantial support for expanding hydrogen energy.”

Source: Korea Institute of Science and Technology (Content may be edited for style and length)

0

Comments

Want to join the conversation?

Loading comments...