COF Scaffold Membrane with Gate‑lane Nanostructure for Efficient Li+/Mg2+ Separation

•February 17, 2026

0

Why It Matters

The breakthrough lifts the long‑standing permeability‑selectivity trade‑off, enabling energy‑efficient lithium extraction from high‑Mg brines and accelerating the supply chain for electric‑vehicle batteries.

Key Takeaways

- •True Li+/Mg2+ selectivity reaches 231.9

- •Li+ flux 11.5 L·m⁻²·h⁻¹·bar⁻¹

- •Membrane rejects >99% Mg2+ for 7 days

- •Gate‑lane architecture creates separate Li+ and Cl- lanes

- •Roll‑to‑roll fabrication enables scalable spiral‑wound modules

Pulse Analysis

The surge in electric‑vehicle production has intensified demand for lithium, yet traditional brine extraction struggles with the “permeability‑selectivity” dilemma: membranes that let lithium through often allow magnesium to slip through, inflating processing costs. Brine sources such as the Salar de Atacama contain Mg²⁺ concentrations up to 50 times higher than Li⁺, making selective separation a critical bottleneck for sustainable supply chains. Emerging nanofiltration platforms aim to address this gap, but most fall short on either flux or rejection, limiting commercial viability.

The newly reported COF scaffold membrane tackles the problem with a dual‑layer gate‑lane architecture. A 20 nm polyurea gating layer, densely charged positively, acts as a Mg²⁺ barrier, while an underlying COF/PEI scaffold forms parallel nano‑lanes that preferentially conduct Li⁺ and Cl⁻ ions. Molecular dynamics and DFT simulations confirm spatial segregation of charge carriers, translating into a true selectivity of 231.9—far above the ideal benchmark of 80.5. Coupled with a water permeance of 11.5 L m⁻² h⁻¹ bar⁻¹, the membrane delivers high throughput with minimal energy input, and maintains >99% Mg²⁺ rejection across a broad pH range for a week.

Beyond laboratory metrics, the membrane’s thin 135 nm profile and vacuum‑filtration roll‑to‑roll production align with existing spiral‑wound module manufacturing lines, smoothing the path to scale‑up. Its robustness against fouling and chemical attack positions it for direct integration into lithium‑brine plants, seawater pretreatment, and battery‑electrolyte purification. Future work will explore anti‑scaling surface treatments and cost‑effective COF synthesis, while the gate‑lane concept could be adapted for other divalent/monovalent separations such as K⁺/Ca²⁺. By converting ion‑mixing penalties into separation bonuses, this technology could reshape the economics of lithium recovery and support the broader clean‑energy transition.

COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation

Nanotechnology Now · Press Release

Location: Shanghai, China

Date: January 30 th, 2026

Abstract

As the global shift to clean energy accelerates, securing a stable lithium supply becomes critical, yet conventional extraction methods struggle with the “permeability‑selectivity” trade‑off when separating Li⁺ from chemically similar Mg²⁺ in salt‑lake brines. Researchers from Tianjin University, National University of Singapore and Sichuan University—led by Prof. Zhongyi Jiang, Prof. Runnan Zhang and Prof. Sui Zhang—report a covalent‑organic‑framework (COF) scaffold membrane whose gate‑lane architecture delivers record‑high true Li⁺/Mg²⁺ selectivity together with high Li⁺ flux. The work offers a blueprint for next‑generation ion‑separation membranes that can harvest battery‑grade lithium with unprecedented efficiency.

COF scaffold membrane with gate‑lane nanostructure for efficient Li⁺/Mg²⁺ separation

Why Gate‑Lane COF Membranes Matter

-

Favorable Ion‑Mixing Effect: True selectivity (231.9) far exceeds ideal selectivity (80.5) at a Mg²⁺/Li⁺ mass ratio of 50, turning multi‑ion interference into a separation booster instead of a penalty.

-

High Li⁺ Permeability: 11.5 L m⁻² h⁻¹ bar⁻¹ water permeance with only a 135 nm thickness ensures low energy consumption and compact module design.

-

Superior Stability: >99 % Mg²⁺ rejection is maintained for 7 days under 5 bar, 5000 ppm MgCl₂, pH 3–11, demonstrating robustness for real‑brine processing.

Innovative Design and Features

-

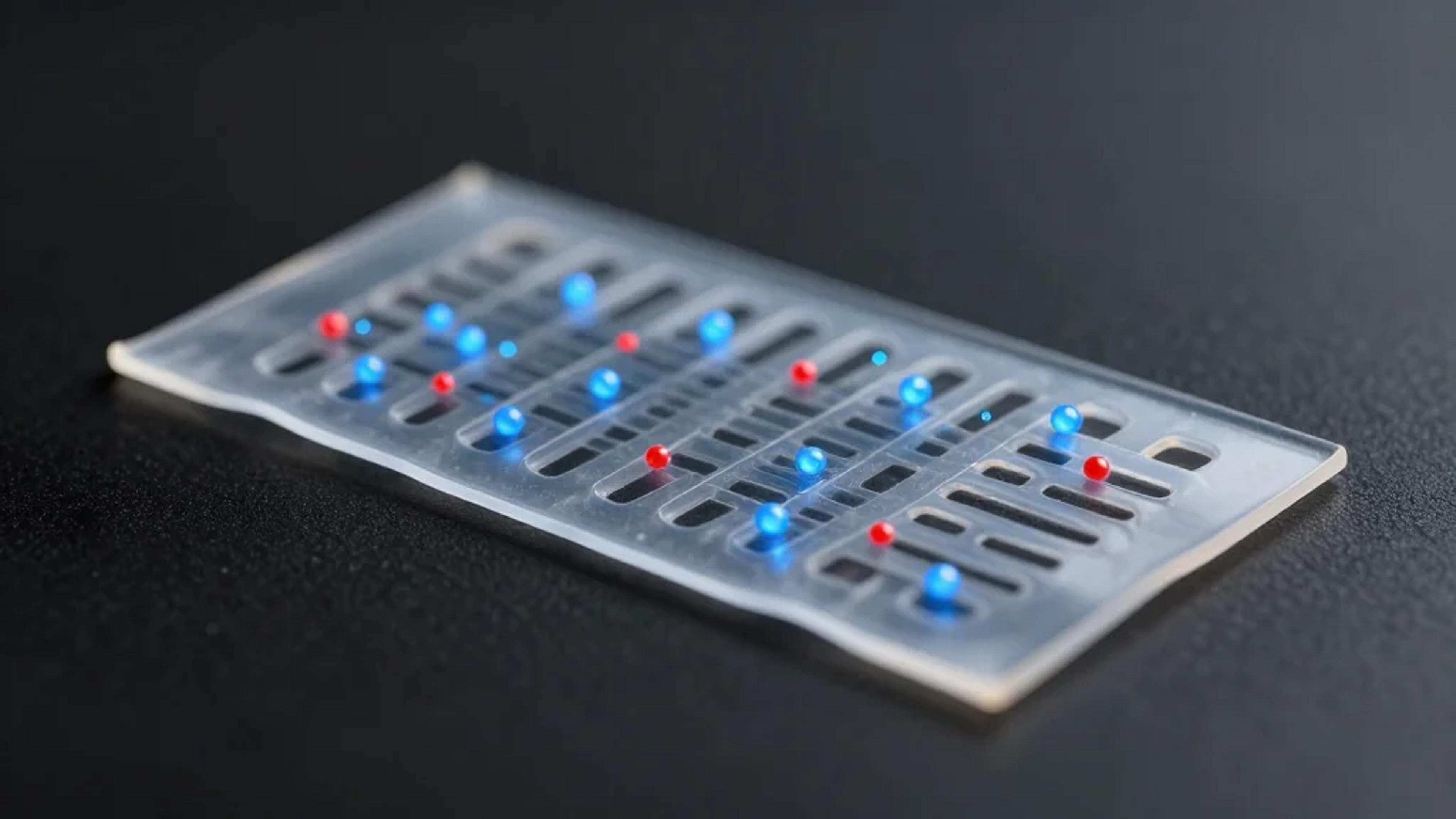

Gate‑Lane Nanostructure: A 20 nm polyurea “gating” layer (small pores, high positive charge) rejects Mg²⁺, while an underlying COF/PEI “permeating” layer forms separate Li⁺ and Cl⁻ nano‑lanes that accelerate Li⁺ transport.

-

Charge‑Asymmetric Scaffold: Positively charged COF nanosheets attract Cl⁻ to create “Cl⁻ lanes”; lower‑charged PEI chains provide “Li⁺ lanes”, achieving spatial segregation verified by in‑situ MD simulations and DFT calculations.

-

Tunable Architecture: Varying the COF/PEI mass ratio from 0.001 to 0.1 switches the membrane from hybrid to scaffold, allowing precise control of pore size (MWCO 335 Da), surface zeta potential (+55.7 mV) and thus selectivity.

Applications and Future Outlook

-

Lithium Extraction from Brines: At Mg²⁺/Li⁺ = 50 the permeate ratio drops to <0.22, cutting more than 200‑fold of original Mg content and surpassing all reported positively charged nanofiltration membranes.

-

Seawater & Battery‑Electrolyte Pretreatment: >98 % rejection of Ca²⁺ and Mg²⁺ protects downstream reverse‑osmosis modules and enables high‑purity electrolyte salts for Li‑ion batteries.

-

Modular Upscaling: Vacuum‑filtration fabrication is roll‑to‑roll compatible; 1.54 cm² lab cross‑flow results scale linearly with pressure, indicating an easy path to commercial spiral‑wound elements.

-

Challenges & Opportunities: Long‑term fouling under natural brine, anti‑scaling surface modification and cost‑effective COF synthesis at tonne scale are next targets. Future work will also extend the gate‑lane concept to other mono/divalent separations such as K⁺/Ca²⁺ and Na⁺/Mg²⁺.

This comprehensive study demonstrates that hierarchical, charge‑asymmetric COF membranes can turn the “ion‑mixing penalty” into a separation bonus, breaking the traditional permeability‑selectivity ceiling. It underscores the power of integrating precise chemistry, advanced spectroscopy and molecular simulations to design membranes for sustainable metal recovery.

For More Information

Contact: Bowen Li

Shanghai Jiao Tong University Journal Center

Office: 021‑62800059

0

Comments

Want to join the conversation?

Loading comments...