Why It Matters

The technique provides a scalable route to engineer multifunctional nanomaterials with tailored properties, accelerating development of next‑generation batteries, catalysts, and information‑processing devices.

Key Takeaways

- •DNA scaffolds template inorganic nanostructures.

- •Vapor and liquid infiltration convert DNA to metal frameworks.

- •Platform enables 3D nanomaterials for energy, photonics, electronics.

- •Works with metals, oxides, semiconductors, hybrids.

- •Offers bottom‑up fabrication beyond existing methods.

Pulse Analysis

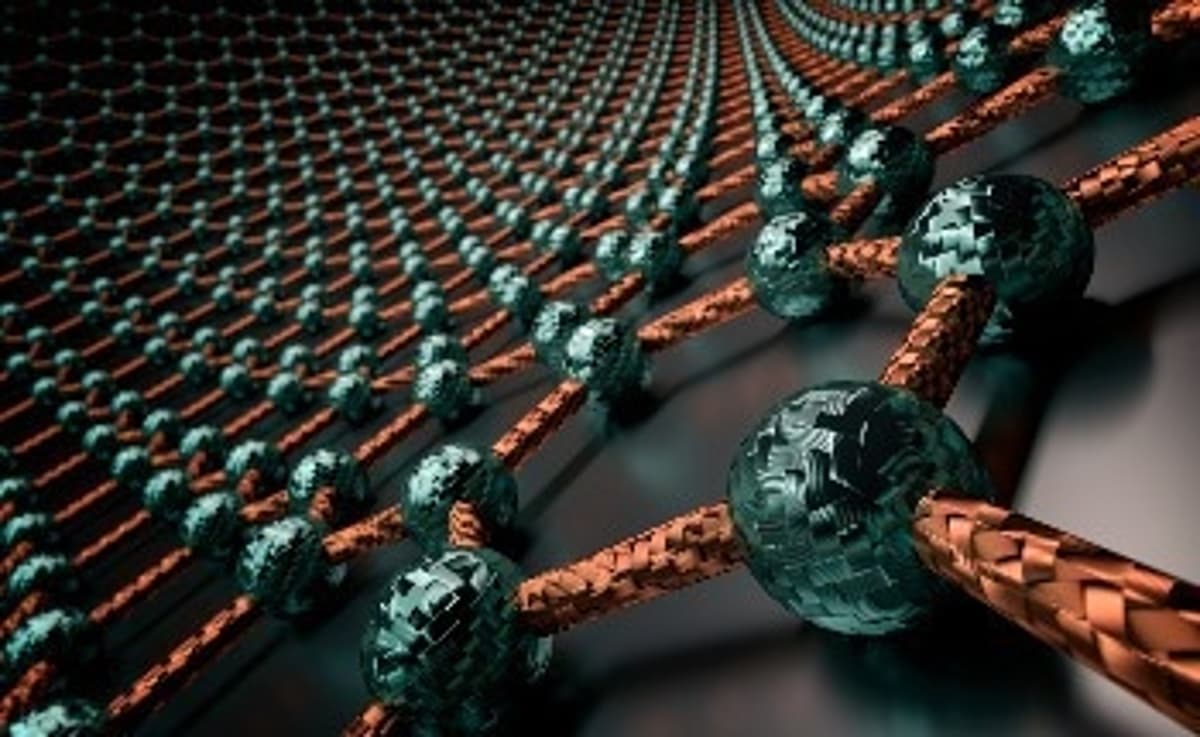

DNA nanotechnology has long promised programmable assembly at the nanoscale, yet translating these delicate structures into robust, functional materials has remained elusive. The new platform leverages the inherent addressability of DNA to build three‑dimensional lattices, then systematically replaces the organic framework with inorganic constituents. This conversion sidesteps the mechanical fragility of pure DNA constructs while preserving the precise spatial arrangement dictated by base‑pairing rules, delivering a versatile template for a wide range of nanomaterials.

The core of the process involves dual infiltration pathways: vapor‑phase precursors penetrate deep into the DNA scaffold, bonding to internal sites, while liquid‑phase chemicals coat and fill remaining voids. By alternating or combining these steps, researchers can deposit metals, metal oxides, semiconductors, or hybrid composites with nanometer‑scale fidelity. Compared with traditional top‑down lithography, this bottom‑up method offers unprecedented control over composition and architecture, enabling the creation of porous, interwoven networks that would be impractical to etch or print using conventional techniques.

Industries poised to benefit include energy storage, where high‑surface‑area electrode frameworks can boost battery capacity, and photonics, where engineered band‑gap materials enable novel light‑manipulation devices. Microelectronics may also see gains from three‑dimensional interconnects that reduce wiring complexity. As the approach matures, integration with existing semiconductor manufacturing lines could accelerate commercialization, while further research into scalable DNA synthesis and precursor chemistry will expand the material palette and drive broader adoption.

DNA Templates for 3D Nanomaterial Design

0

Comments

Want to join the conversation?

Loading comments...