Projecting Light to Dispense Liquids: A New Route to Ultra-Precise Microdroplets

•February 17, 2026

0

Why It Matters

The ability to generate uniform nanoliter droplets with sub‑percent error enables higher‑throughput, lower‑cost biochemical assays, accelerating diagnostics and drug discovery. It also reduces device complexity, facilitating broader adoption of digital microfluidics.

Key Takeaways

- •Light patterns act as reconfigurable virtual electrodes

- •Achieves 0.45% relative error for 36 nL droplets

- •Coefficient of variation stays below 2.5% across sizes

- •Demonstrated PCR success in sub‑200 nL droplets

- •Simplifies chip design, eliminating complex electrode fabrication

Pulse Analysis

Precise liquid handling lies at the heart of modern biochemical workflows, yet conventional electrowetting platforms struggle with flexibility and reproducibility at the nanoliter scale. Fixed electrode arrays impose design constraints, while mechanical actuation introduces variability that can compromise assay fidelity. As laboratories push toward miniaturization to conserve reagents and increase throughput, a more adaptable method for droplet generation has become a critical bottleneck.

The newly reported optoelectrowetting system sidesteps these limitations by projecting programmable light patterns onto a dielectric surface, effectively forming "virtual electrodes" that steer droplet morphology in real time. Dynamic illumination controls the necking and pinch‑off phases, delivering droplets as small as 36 nL with a relative error of just 0.45 % and a coefficient of variation below 2.5 %. Validation through on‑chip polymerase chain reaction demonstrates that biochemical reactions proceed identically to traditional pipetting, confirming the platform’s suitability for sensitive molecular assays.

Beyond laboratory precision, the technology promises to reshape the commercial microfluidics landscape. By removing the need for intricate electrode fabrication, manufacturers can produce cheaper, reconfigurable chips that adapt to diverse protocols without hardware redesign. This flexibility accelerates development cycles for point‑of‑care diagnostics, high‑throughput drug screening, and organ‑on‑chip studies, where consistent sub‑200 nL volumes are essential. As optical control matures, integration with AI‑driven pattern generation could further automate assay optimization, positioning light‑guided droplet dispensing as a cornerstone of next‑generation digital microfluidic platforms.

Projecting light to dispense liquids: A new route to ultra-precise microdroplets

Nanotechnology Now · Press Release · Beijing, China · Posted on January 30 th, 2026

Abstract

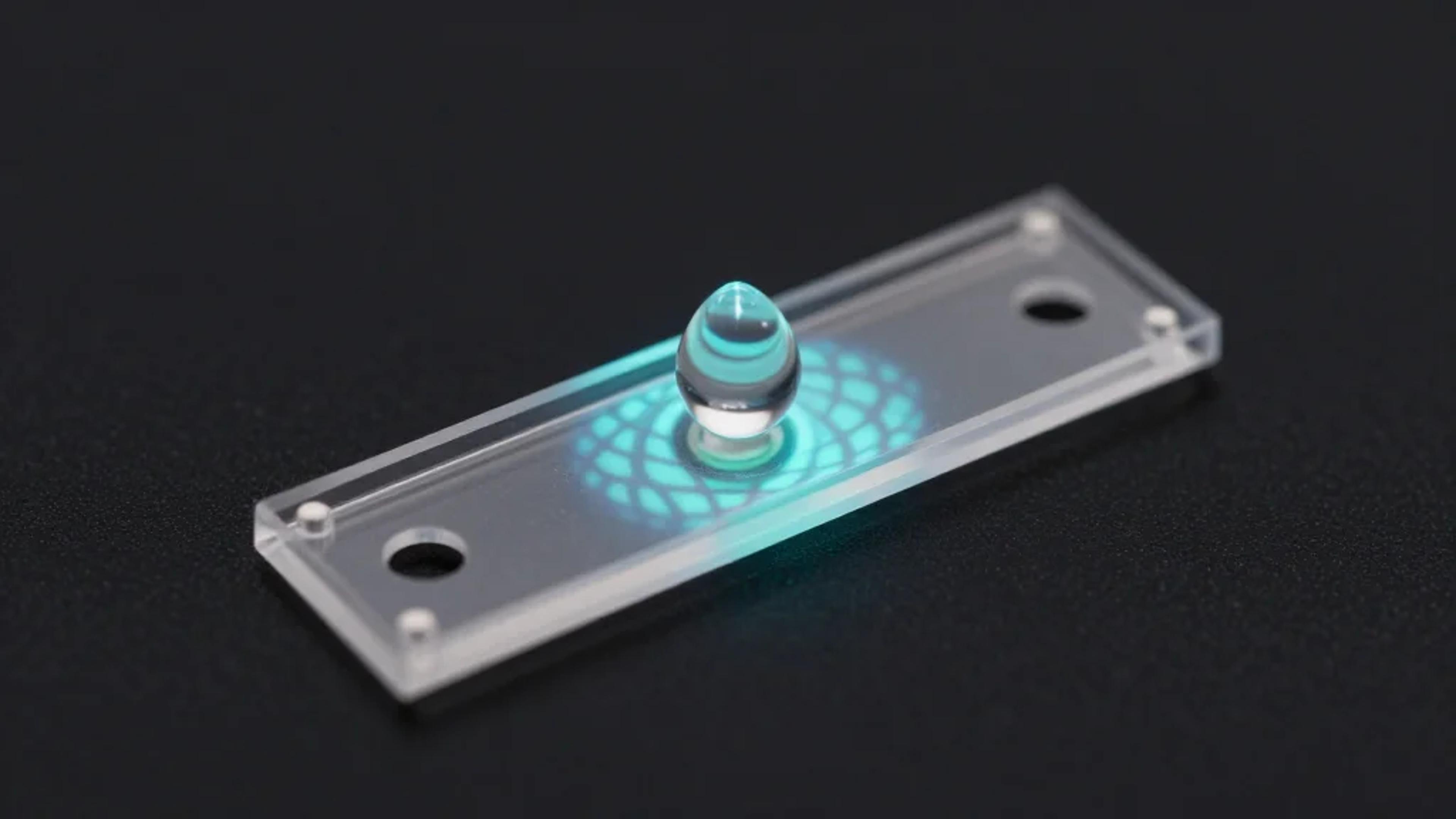

Precise control of tiny liquid volumes is essential for modern biochemical analysis, yet reliably dispensing nanoliter‑scale droplets remains technically challenging. This study presents a light‑controlled droplet dispensing strategy that enables highly accurate generation of tunable nanoliter droplets on a microfluidic chip. By combining optoelectrowetting with dynamically designed light patterns, the system guides droplets to deform, shrink, and detach in a controlled manner. The approach achieves exceptional volume consistency across a wide range of droplet sizes and supports stable formation of uniform droplet arrays. Beyond technical precision, the work demonstrates that light‑driven droplet control can reliably support small‑scale biochemical reactions, offering a powerful alternative to conventional liquid‑handling methods.

Article

Droplet‑based microfluidic systems are widely used for biochemical assays, diagnostics, and drug discovery because they reduce reagent consumption and improve reaction control. However, dispensing individual droplets with high accuracy is difficult, especially at volumes below hundreds of nanoliters. Traditional electrowetting systems rely on fixed electrodes, which limit flexibility and require complex fabrication. Optical control methods offer greater freedom but often suffer from inconsistent droplet size and poor reproducibility. In particular, uncontrolled droplet necking and random pinch‑off during dispensing lead to large volume errors. Based on these challenges, there is a strong need to develop a controllable, high‑precision droplet dispensing strategy capable of stable nanoliter‑scale operation.

Researchers from the Southern University of Science and Technology, reporting on November 28 2025 in Microsystems & Nanoengineering (DOI: 10.1038/s41378-025-01071-6), describe a new optoelectrowetting‑based droplet dispensing system that uses programmable light patterns to precisely control droplet formation. The study introduces a dynamic light‑guided strategy that enables reliable dispensing of nanoliter droplets with tunable volumes. By projecting tailored optical patterns onto a microfluidic chip, the system achieves accurate droplet shaping, separation, and transport, demonstrating both high precision and strong reproducibility in small‑volume liquid handling.

The core innovation of the study lies in a dynamic light‑pattern design that actively controls droplet deformation and pinch‑off during dispensing. Instead of relying on fixed electrodes, the system creates “virtual electrodes” through localized illumination, allowing droplets to be guided solely by projected light. A specially designed necking light pattern plays a critical role by stabilizing the liquid bridge that forms between the parent droplet and the emerging daughter droplet.

During dispensing, the droplet first extends under illumination, then undergoes a controlled back‑pumping step that reshapes the liquid to match the light pattern. This process slows down the pinch‑off event, eliminating random splitting and significantly improving volume accuracy. Through systematic optimization of light‑pattern geometry, voltage, and necking position, the researchers achieved a minimum relative error of 0.45 % and a coefficient of variation of 2.49 % for droplets around 36 nanoliters.

The system also demonstrated strong flexibility, accurately dispensing droplets across a broad size range while maintaining precision below commonly accepted error thresholds. Importantly, the researchers validated the platform using polymerase chain reaction (PCR) amplification, showing that on‑chip droplets performed comparably to manually pipetted samples, even at volumes below 200 nanoliters.

“This work shows that light can be used not just to move droplets, but to precisely define their final volume,” said the study’s corresponding author. “By controlling the entire dispensing process with programmable optical patterns, we eliminate many sources of randomness that limit conventional microfluidic systems. The ability to generate uniform nanoliter droplets with such low error opens new possibilities for automated biochemical workflows, especially where consistency and miniaturization are critical.”

The light‑guided droplet dispensing strategy offers a versatile solution for lab‑on‑a‑chip platforms used in molecular diagnostics, drug screening, and organ‑on‑chip research. Its ability to reliably handle sub‑200‑nanoliter volumes addresses a long‑standing gap between conventional pipetting and microfluidic automation. Because the system avoids complex electrode fabrication, it also simplifies device design and improves scalability. More broadly, the work highlights how optical control can transform digital microfluidics into a flexible, reconfigurable tool for precision chemistry and biology, with potential impact across clinical testing, pharmaceutical development, and high‑throughput biochemical analysis.

Funding Information

This work was financially supported in part by:

-

Guangdong‑Hong Kong‑Macau Joint Laboratory on Micro‑Nano Manufacturing Technology (Grant No. 2021LSYS004)

-

National Natural Science Foundation of China (Grant No. 62403231)

-

National Natural Science Foundation of China (Grant No. 31927802)

-

Shenzhen Science and Technology Innovation Commission (Grant No. RCJC20200714114436046)

About Microsystems & Nanoengineering

Microsystems & Nanoengineering is an online‑only, open‑access international journal devoted to publishing original research results and reviews on all aspects of micro‑ and nano‑electromechanical systems, from fundamental to applied research. The journal is published by Springer Nature in partnership with the Aerospace Information Research Institute, Chinese Academy of Sciences, and is supported by the State Key Laboratory of Transducer Technology.

Contact

Na Li

Microsystems & Nanoengineering

0

Comments

Want to join the conversation?

Loading comments...